Ballast tractor tyres to support motor skills

Ballast tractor tyres to support motor skills

SUMMARY:

Why is ballasting useful?

The benefit is simple and clear: with right ballasting, you should gain in efficiency in the field.

The tractor's grip is improved, so your machine can provide better traction. And better traction means a lower rate of slippage, which not only saves fuel but also means you should work more efficiently and support tyre longevity.

How to ballast tractor tyres?

Ballasting is done by adding weights. Some farmers do this themselves, but you can also ask your dealer to provide it. For good traction, we recommend you add around 50 kilograms per horsepower. Multiply 50 kg by the number of horses on the tractor and you get the weight you need.

The objective is to balance the load between the front and rear axles of the tractor. For example, if an implement mounted at the rear of the tractor unbalances the tractor by taking weight off the front, it may be necessary to add weight at the front to maintain balance.

In the case of tractors fitted with front loaders, it may be necessary to add weights at the rear to compensate for the imbalance.

Ballasting is crucial to support a tractor's power-to-weight ratio, especially when it is faced with difficult working conditions such as deep ploughing. A tractor that is not heavy enough will have difficulty exerting effective traction in such conditions, hence the need to add ballast to support its traction capacity and overall efficiency.

Looking for balance

A balance between the loads at the front and rear of the tractor is sought to ensure its efficiency.

For example, on certain models of tractor, a distribution of 40% of the load at the front and 60% at the rear is recommended due to the size and layout of the transmission.

ballasting helps to restore balance between the front and rear of the tractor

However, recommendations can vary depending on the manufacturer and type of tractor. Some manufacturers offer specific recommendations, while others leave this decision to the discretion of the dealer, who can adjust the load distribution to suit the customer's specific needs and limitations.

As we said earlier, if a heavy implement is attached to the rear of the tractor, it is necessary to add weight to the front to rebalance. However, a common mistake is to ballast a tractor at the front when it is already heavy, which causes a loss of weight at the rear, leading to a loss of traction and overloading of the front axle. This often results in an increase in the slippage rate, which is usually the first visible symptom of this imbalance. And slippage doesn't just affect the mechanics and tyres, it also damages the soil and increases fuel consumption.

If you notice a lack of traction or inadequate handling of your farm machinery, we recommend that you ask your dealer for advice. He will be able to provide you with the information you need to optimise ballasting in order to obtain a more appropriate power-to-weight ratio.

How are ballast weights fixed?

Weights can be fixed to the wheels.

They can also be fitted to various points on farm machinery, such as front or rear lifting gear, and sometimes under the tractor to lower its centre of gravity while maintaining the balance of loads between front and rear.

How are ballast weights fixed

How do water ballast tractor tyres?

Ballasting tyres with water / liquids

In some specific cases, to increase a machine's weight or lower it's centre of gravity, tyres can be ballasted with liquid.

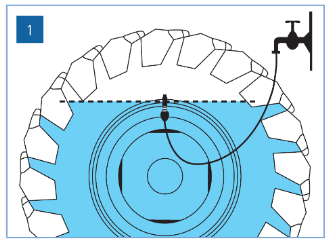

Agricultural valves are usually "air and water" valves. This means tyres can be filled up to a maximum level of 75% with liquid (water + anti-freeze) (diagram 1).

Ballasting tyres with liquids

In winter, temperatures may fall below freezing and at 0°C the use of a Glycol based anti-freeze product is required *.

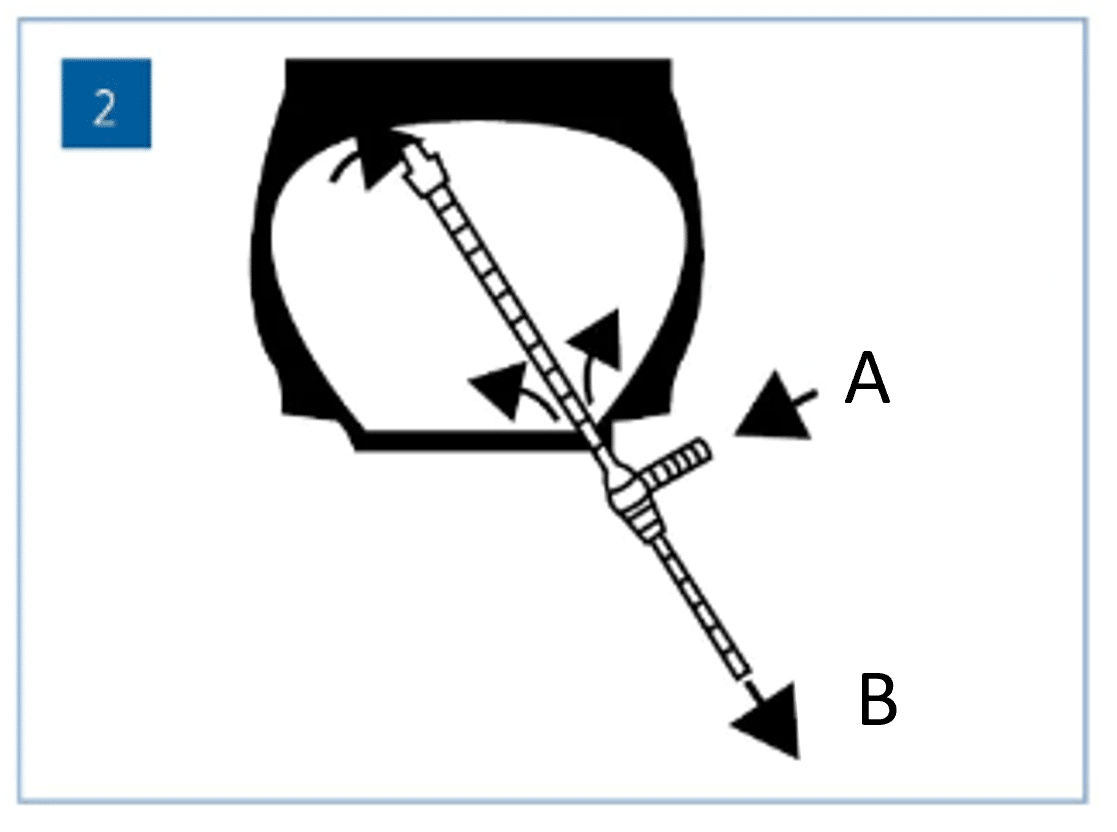

To water ballast to the maximum level, fill the inner tube or Tubeless tyre with liquid up to the level of the valve (valve at highest point), while releasing the air (diagram 2).

As there is less air to provide pressure (approximately 25% of total volume), it is vital to regularly monitor pressure levels. We recommend a monthly check.

inflation and pressure are adjusted using air

A: Water B: air

Ballasting tubeless tyres with water / liquids

Assemble and position the tyre:

- Deflate the tyre to a low pressure (roughly 0.5 bar)

- Position the valve at the highest point,

- Start to fill the tyre with liquid (water + anti-freeze), to a maximum of 75% while releasing the air (diagram 2),

- Finish inflating with air and adjust the pressure.

Ballasting on other farm machinery

Ballasting is not just for tractors; it can also be relevant to other farm machinery.

For example, in the case of forage harvesters or combine harvesters, some manufacturers offer the option of adding extra weight to the rear of the machine to balance it against the implements that will be installed at the front.

Self-propelled sprayers may also require ballasting, particularly when used on sloping terrain.

In viticulture, ballasting is commonly used because the terrain in vineyards can be particularly steep. Ballasting is used on high-clearance tractors and harvesting machines, particularly grape harvesters. High-clearance tractors have a relatively high centre of gravity, which makes them more likely to tip over when operating on steep terrain. To improve safety in such conditions, it is common practice to ballast the machine with weights or liquid to lower its centre of gravity.

Other articles that might interest you:

Need more advice? Discover our tyre maintenance and caring guide

* As Michelin is not involved in the design of those products, MICHELIN’s warranty specifically states that MICHELIN will not be held responsible for any associated damages to the tyres.