Truck tyre repair and damage prevention

Truck tyre repair and damage prevention

In the transport sector, where trucks cover long distances with heavy loads, tyres play a crucial role in terms of performance, safety and cost optimisation. But tyre damage can occur and compromise this. What warning signs can you spot? Can a tyre always be repaired? What preventive measures should you take? Find all the answers in our article.

The warning sign that your tyres may need repairing

An abnormal loss of pressure is the signal to watch out for. It indicates a problem that may require tyre repair or replacement. When you notice a tyre pressure drop of 20%, it's imperative to have the inside of the tyre inspected to identify the damage.

A pressure fluctuation of up to 10% can be tolerated, but beyond this point the internal structure of the tyre may be seriously compromised.

What are the risks if my tyre is under-inflated?

Continuing to drive with an under-inflated tyre is not advisable for several reasons:

Firstly, an under-inflated tyre flexes excessively, increasing its structural fatigue. Overheating can occur, as well as a possible rapid deflation, endangering the driver and other road users.

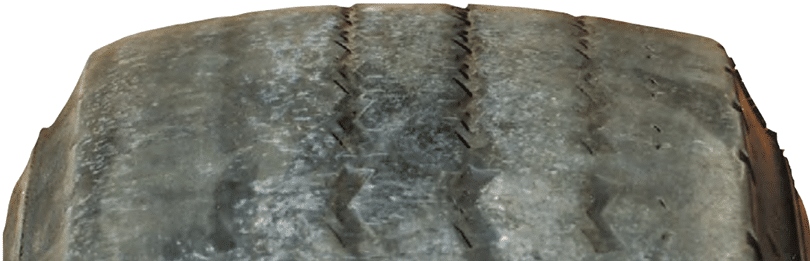

Tyres operating at incorrect inflation pressures can result is uneven wear, leading to premature removal of the tyre.

In the case of twin tyres, it's even worse because if one tyre is properly inflated and the other is not, the under-inflated one will slip much more and wear faster, leading to service disruption and emergency repairs that generate additional costs for the company.

Uneven wear due to under-inflation

Under-inflated truck tyre

In addition to the risks mentioned above, under-inflated tyres can have other inconveniences: reduced tyre pressure increases rolling resistance, which leads to higher fuel consumption during journeys. For transport companies, this means higher operating costs and a larger carbon footprint.

How can you reduce the risks of tyre damage?

Regular maintenance and frequent checking of tyre pressure are essential preventive measures to limit the risks. There are two ways of monitoring tyre pressure:

Pressure monitoring by TPMS

From 1 July 2024, all trucks newly registered in Europe must be fitted with tyre pressure monitoring systems (TPMS)(1). Read our article "New TPMS Regulations on the Horizon" for more information.

The aim of this regulation is to ensure that truck drivers are alerted to any drop in tyre pressures, in order to avoid potential accidents caused by under-inflated tyres.

Trucks registered before this date are not required to fit TPMS kits retrospectively, although it is technically possible to do so with different types of sensors. We will discuss recommendations in this case in the section entitled "Pressure monitoring without TPMS".

Reduce the risk of tyre repairs by monitoring pressure

TPMS comes in two main forms: direct systems, which use sensors mounted inside the tyres, and indirect systems, which use ABS sensors to monitor wheel speed. Although indirect systems are cheaper and easier to install, they are also less accurate than direct systems.

Pressure monitoring without TPMS

In the absence of TPMS, we recommend that drivers check their tyre pressures at least once a month, and particularly before long journeys.

A visual inspection helps to detect visible anomalies, such as nails, cracks, cuts, deformations or embedded objects.

We also recommend checking tyre pressures with a pressure gauge, as a visual inspection is not enough to determine accurate inflation pressures.

Technician checking the pressure of the tyre on a heavy truck vehicle

Causes of tyre damage

Most damage to HGV tyres is caused by impacts with objects on the road, such as stones, scrap metal or kerbs. Perforations caused by screws are particularly common because of their ability to penetrate the tyre easily. Depending on the nature and location of the puncture, it may not always be repairable.

Tyres are also vulnerable to damage caused by overloading.

When a heavy goods vehicle is carrying loads in excess of recommended limits, the load carried by the tyres increases and can lead to premature wear and structural failure. Always make sure you comply with the maximum load specified for the truck's tyres.

Poor loading practices, such as uneven weight distribution, will result in the load being poorly distributed across the various axles, potentially overloading some of them and causing tyre damage.

Poor loading practices can cause truck tyre damage

Tyre repairs

Tyre repairs, carried out by professionals, must comply with strict standards to ensure safety. Specialist technicians evaluate the extent of the tyre damage and decide whether a repair is possible or whether the tyre needs to be replaced.

There are two repair methods commonly used to restore damaged tyres: cold or hot repair.

Cold repair

This method involves the application of a repair material to the damaged area of the tyre without the need for high heat. Cold repairs often use rubber patches or plugs that are bonded using a special adhesive.

- Advantages: Cold repairs are generally quicker and easier to carry out. It does not require sophisticated equipment, making it accessible for repairs in the field or in less well-equipped workshops.

- Disadvantages: Cold repairs are less durable than hot repairs. They can be more likely to fail under difficult driving conditions, particularly on tyres that are subjected to heavy loads or high temperatures. What's more, with a cold repair there is a risk of oxidation spreading to the tyre's crown block and therefore a rejection for a future retread.

This method is recommended for temporary repairs or minor tyre damage that does not compromise the tyre's integral structure.

Hot repair

A hot repair is recommended for more serious tyre damage or large punctures affecting the inner plies of the tyre. It is particularly useful for truck tyres that are subjected to extreme driving conditions. It involves the application of heat to vulcanise the repair rubber, fusing the repair material to the original tyre. This is usually done in a controlled environment using specialist equipment.

- Advantages: Hot repairs offer superior mechanical integrity and durability. The vulcanisation process ensures that the patch or plug becomes an integral part of the tyre, increasing its strength and longevity. It also increases the likelihood that the casing can be retreaded in the future.

- Disadvantages: This method is more expensive and requires specific equipment and technical skills. It also takes longer to carry out.

Which tyre repair method is best?

The tyre repair method is chosen according to the severity of the damage and the conditions in which the tyre is used.

Cold repair means a quick repair for the driver, but with risks on:

- The durability of the repair,

- Oxidation of the crown block and therefore the risk of not being able to retread the casing in the future,

- A slow loss of pressure.

For these reasons, Michelin recommends a hot repair.

Non-repairable tyre damage

When a professional carefully inspects the inside of a tyre, he or she may detect mottling or discolouration. These signs indicate tyre damage that cannot or must not be repaired. If this is the case, either the casing is accepted for retreading, or tyre replacement is unavoidable.

If you have the slightest doubt about the condition of your tyres, don't hesitate to consult your tyre dealer.

Mottling on truck tyre

Other articles to find out more:

Need more advice? Discover all MICHELIN truck tyre tips

(1) Sourcing: UN Regulation No 141 – Uniform provisions concerning the approval of vehicles with regard to their Tyre Pressure Monitoring Systems (TPMS)