How to choose a heavy duty truck tyre inflator?

How to choose a heavy duty truck tyre inflator?

Maintaining the correct tyre pressure for heavy goods vehicles (HGVs) is crucial to the safety of the driver and other road users. It also plays an essential role in the economic and operational efficiency of vehicles. But which tyre inflator should you choose for effective pressure management of your HGV? Let's take a look at the different solutions.

SUMMARY:

The different types of inflation device

Tyre compressors

Tyre compressors are machines that store air under pressure for later use. They can handle large volumes of air and high pressures, making them ideal for heavy vehicle tyres.

Tyre inflators

Tyre inflators are simpler and often portable devices designed to inflate tyres directly. They can be manual or digital, and some include built-in compressors for added convenience.

Automated inflation systems

This is advanced equipment that automatically monitors and adjusts tyre pressure to maintain optimum levels in real time.

Let's look at these devices in more detail.

Focus on truck tyre compressors

Portable tyre compressor

Portable tyre compressor

Easy to transport and ideal for mobile use, a portable tyre compressor allows tyres to be inflated in the field, which is practical for heavy vehicles that travel long distances and may experience pressure problems away from workshops. Portable compressors need to be powerful enough to achieve the high pressures required, yet compact and robust enough to withstand tough working conditions.

- Safety: Ensure the vehicle is parked on a level surface and the handbrake is engaged

- Connect the portable tyre compressor to the tyre valve and the vehicle's power source.

-

Switch on the compressor and monitor the pressure using a pressure gauge.

-

Switch off the compressor once the recommended pressure has been reached and disconnect it carefully.

Stationary tyre compressor

Stationary tyre compressor

Stationary tyre compressors are fixed and generally used in workshops or garages. They offer superior capacity and durability, often being equipped with more powerful motors and larger air tanks. They are ideal for regular, intensive use, allowing fast, efficient inflation of the tyres of many heavy vehicles.

- Safety: Use protective devices such as safety glasses and gloves.

- Attach the tyre compressor hose to the tyre valve and switch on the stationary compressor.

- Monitor the pressure with a pressure gauge until the desired pressure is reached.

- Switch off the tyre compressor and remove the hose from the valve.

High pressure tyre compressor

High pressure tyre compressors

foot pump on the floor next to the car and wheel

High-pressure tyre compressors are specially designed to achieve the high pressures required by heavy-duty vehicle tyres. They are capable of generating much higher pressure levels than standard compressors, ensuring that tyres are inflated correctly and safely.

-

Safety: Check that all connections are secure to avoid air leaks

-

Connect the high pressure compressor to the tyre valve and switch it on.

-

Monitor the pressure carefully and turn off the compressor when the desired pressure is reached.

-

Carefully disconnect the hose from the valve.

High Capacity (CFM)

high capacity compressor cfm

For heavy vehicle tyres, a high CFM is crucial to ensure fast inflation and reduce downtime. CFM (Cubic Feet per Minute) measures the amount of air a compressor can produce per minute. Compressors with a high CFM allow tyres to be inflated more efficiently, which is essential for time-sensitive operations.

-

Safety: Use hearing protection if the compressor is noisy

-

Connect the high capacity compressor to the tyre valve.

-

Turn on the compressor and check the pressure with a manometer.

-

Stop the compressor when the correct pressure is reached, then disconnect the hose.

Focus on truck tyre inflators

Tyre inflators also come in different forms:

Manual tyre inflator

Manual tyre inflator

These inflators require manual action to pump air into the tyres. They are often used as back-up solutions and are generally more affordable, but they require more time and effort to achieve the desired pressure.

- Safety: Make sure the tyre is cold before starting inflation

- Connect the manual tyre inflator to the tyre valve.

- Pump manually until the recommended pressure is reached, checking with a pressure gauge.

- Disconnect the tyre inflator from the valve.

Digital tyre inflator

Digital tyre inflator

Digital tyre inflators are equipped with electronic sensors and displays for accurate pressure reading. They allow you to program the desired pressure and automatically stop inflation once this pressure has been reached. This reduces the risk of under- or over-inflation and offers greater convenience and accuracy for the user.

They allow you to program the desired pressure and automatically stop inflation once this pressure has been reached. This reduces the risk of under- or over-inflation and offers greater convenience and accuracy for the user.

-

Safety: Use a calibrated pressure gauge to check the final pressure

-

Connect the digital tyre inflator to the tyre valve.

-

Set the desired pressure on the inflator and switch it on.

-

The inflator will stop automatically once the pressure is reached, then disconnect it.

Automated tyre inflator

Automated tyre inflator

They are particularly useful for heavy vehicle fleets, as they maintain tyres at the optimum pressure without manual intervention, improving efficiency and safety throughout the fleet.

These advanced systems automatically monitor and adjust tyre pressure on a continuous basis.

-

Safety: Follow the manufacturer's instructions for installing and using the system

-

Make sure the automated system is correctly installed and connected to the tyre valve.

-

Activate the system, which will automatically monitor and adjust the pressure.

-

Check the final pressure with a manometer to confirm.

The importance of a manometer

Manometers (or tyre pressure gauges) are essential devices for measuring tyre pressure before and after inflation. Accurate measurement is crucial to ensure that tyres are inflated to the recommended pressure, which ensures vehicle safety and efficiency. You can use either an analogue or digital manometer.

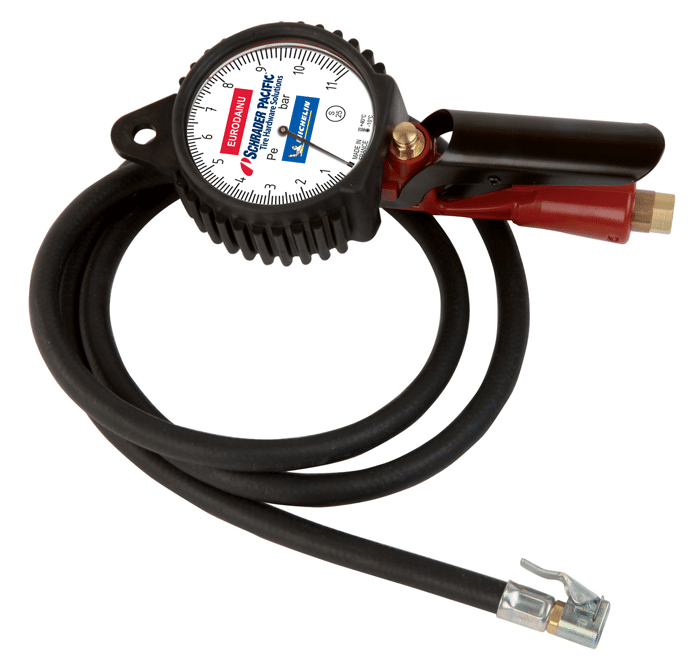

Analogue manometer

Analogue manometer

This manometer uses a needle to indicate the pressure on a dial.

It is simple to use and robust, but can sometimes be less accurate than its digital equivalent.

Digital manometer

Digital manometer

A digital manometer provides an accurate and easy-to-read reading of tyre pressure.

It is often equipped with backlit displays, allowing it to be used in low-light conditions.

Maintenance and safety

To ensure safe and efficient inflation of heavy vehicle tyres, rigorous compressor maintenance is essential. After prolonged use, it is crucial to allow the compressor to cool down to avoid overheating and potential breakdowns.

In terms of safety, we also recommend using compressors fitted with safety features such as automatic shut-off in the event of overheating.

Use inflation tools in accordance with the manufacturer's instructions to apply the pressure recommended by your vehicle manufacturer to your HGV tyres.

Other articles to find out more:

Need more advice? Discover all MICHELIN truck tyre tips