Reduce your operating costs with retread tyres.

Reduce your operating costs with retread tyres

For over a century now, we've been able to bring truck tyres back to life using the tyre retreading technique pioneered by Michelin. In this article, our experts explain the benefits and how we proceed to give your tyres a new lease of life.

SUMMARY:

Tyre retreading reduces your operating costs

There are two economic advantages to tyre retreading for lorries:

- it considerably reduces the cost of replacing tyres, because instead of buying a replacement tyre, you reuse the same one after a retreading operation

- it optimises your TCO (Total Cost of Ownership), i.e. the cost of the tyre's life cycle, since your tyre, once retreaded, will be able to run for longer.

Tyre retreading helps you reduce environmental impact

Here's how you can significantly reduce environmental impact:

- retread tyres imply less raw materials: each tyre retreaded by Michelin saves up to 50 kg (1) of raw materials, a reduction of 70% compared to a new tyre.

- retread tyres imply fewer CO2 emissions: retreading 100 tyres means more than 11,6 tonnes of CO2 (2) are not released into the atmosphere.

Tyre retreading is safe profitable and sustainable

Retread tyres can therefore maximise your profitability and reduce your environmental impact, without compromising safety. Calculate the gains for your truck fleet:

Does tyre retreading compromise safety?

It's a legitimate question to ask. After all, we're talking about putting tyres back on the road that have reached a significant level of wear. Tyres that might no longer be able to be driven in their current state, with this level of wear, without compromising the safety of the driver, any passengers and the load.

But the difference lies in the tyre retreading work we do. It's an operation we've been carrying out for over 100 years, and which we've developed impeccable know-how and technology. We call this quality service MICHELIN Remix.

MICHELIN Remix retreaded tyres use MICHELIN materials, long lasting performance technology and MICHELIN manufacturing procedures to offer the same key performances as new MICHELIN tyres, i.e. the same main characteristics in terms of safety, traction and grip as our new tyres.(3)

To guarantee optimum safety, professionals who have completed a 2-year certificate course check each retreaded tyre and carry out multiple checkpoints:

- X-ray examination,

- Shearography,

- RFID reading,

- Inspection for distortions,

- Detection of micro-perforations,

- Final test when inflated to 10 bar pressure

In other words, you don't have to choose between retreading and safety. Our service takes both into account.

What's more, the MICHELIN Remix factories are all ISO 9001 and ISO 14001 certified, which means that they guarantee optimised management of quality and environmental performance respectively.

Find out more about the MICHELIN Remix tyre retreading service

Truck tyres retreading visual inspection

Please note that retreaded tyres are designed to be fitted to drive axles and trailer axles. We do not recommend mounting them on the first steering axle.

Technology that boost tyre retreadability

Over the years, we have perfected casing technology for our retreading operations:

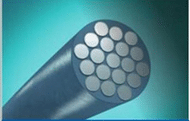

Improved casing durability with new-generation steel cords

Improved casing durability with new-generation steel cords, stronger and more resistant to oxidation.

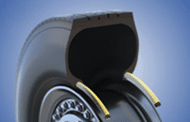

Reinforced heel with premium nylon

Reinforced heel for greater durability with premium nylon that protects the structure of the tyre area in contact with the wheel

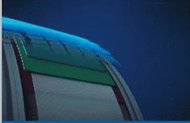

Reinforced casing with a continuous steel wire

Reinforced casing for greater stability and safety.

A continuous steel wire – which can be as long as 400 metres wrapped around the tyre to provide it with greater stability throughout its lifetime.

How we give your tyres several lives

Retreading is at the heart of the circular economy. So is another complementary technique that we also use: tyre regrooving.

By alternating between the two techniques, you can extend the life of your tyres, allowing them to cover many more kilometres than their original life, while reducing the environmental impact compared with buying new tyres.

Step 1- the new tyre

The new tyre

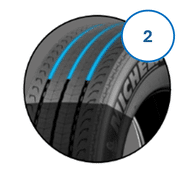

Step 2: the 1rst tyre regrooving

1st regroove

-5% fuel(5), +25% km(6), + traction(4) & grip(4), + 251kg in CO2 savings (7)

Step 3: the 1rst tyre retreading

1st retread

up to +100% km(3) + 115kg in CO2 savings(7)

Step 4: the 2nd tyre regrooving

2nd regroove

-5% fuel(5), +25% km(6) + traction(4) & grip(4) + 251kg in CO2 savings (7)

Discover the MICHELIN Remix service

Other articles to find out more:

Need more advice? Discover all MICHELIN truck tyre tips

(1) In terms of material savings, the average weight of a new MICHELIN tyre is 70 kg*. The weight of a tyre ready to be retreaded weighs 50 kg** on average.

*Internal study based on the MICHELIN truck tyre sizes most sold on the European market: 315/80 R 22.5, 315/70 R 22.5 and 385/65 R 22.5.

**According to a TNPF publication from 2023: “retreading, which, by reusing the casing that represents approximately 70% of a tyre’s weight” (sic). As a result, 70% of 70 kg = approximately 50 kg.

(2) The CO2 saving associated with the retreading operation is calculated from the associated material saving. In terms of material saving, a MICHELIN Remix® retreaded tyre covers up to 100% of the mileage of a new MICHELIN tyre (7). A new tyre weighs 70 kg on average. A new tyre ready to be retreaded weighs 50 kg on average. The CO2 impact of a retreaded tyre is linked to the material saving, or 115 kg of CO2 representing 50 kg of raw material savings, at a rate of 2.3 kg of CO2* per kg of raw materials

(3) The tread compound and pattern of MICHELIN Remix® tyres are largely the same as those used for new MICHELIN tyres. 90% of the MICHELIN Remix® tyre range is manufactured using the same mould and the same materials as new MICHELIN tyres and therefore perform equally well. According to internal tests conducted by the Michelin Research and Technology centre and customer testimonials collected in Europe since 2015.

(4) On wet ground, regrooved tyres offer approx. 10% greater transverse grip and traction compared to the same worn tyres. Internal study carried out by Michelin on a polished concrete track at Ladoux (France) in 2010; results may vary depending on the actual conditions of use, TNPF 2019

(5) 5.4% save in fuel consumption: internal study carried out at the Michelin test tracks in Ladoux (France) on 5 May 2021, under DEKRA supervision (report No. 21CPAEXT-030). For the comparison between new tyres and regrooved tyres (R5 mm), two identical Volvo FH500 trucks were used, fitted with 315/70 R 22.5 MICHELIN X® Line Energy Z2 & D2 tyres and each towing a fully loaded (40 tonnes) Schmitz Cargobull trailer fi tted with 385/55 R 22.5 MICHELIN X® Line Energy T tyres at identical pressures (8.5 b, 7.5 b and 9.0 b). Results may vary depending on weather conditions, road type, tyre size and driving style.

(6) Compared to a worn non-regrooved MICHELIN tyre. Information based on the recommendations made by the French tyre manufacturers’ federation (TNPF) in 2019, according to which the regrooving of worn tyres increases tyre life by using all the available rubber.

(7) The CO2 savings from the Michelin multi-life model, are accentuated thanks to the fuel savings linked to regrooving (up to 5.4%(4)). According to a study under real conditions of use (using 315/70 R 22.5 tyres fitted to the drive and steering axles of a 4x2 truck used for international and national long distance, that have exceeded 50% wear), the average mileage for MICHELIN X® Line Energy Z2 and MICHELIN X® Line Energy D2 tyres is 232,200 km before regrooving* (*Michelin internal source and calculation, based on measurements taken by the Michelin teams during customer inspections on 488 axles, in Austria, Belgium, Croatia, the Czech Republic, France, Germany, Greece, Hungary, Italy, the Netherlands, Poland, Portugal, Romania, Serbia, Slovenia, Spain, and Turkey, over the period from 2020 to 2023), with a simulation based on the results collected suggesting extrapolation of the lifespan until 3 mm remains. The results may vary depending on the weather and road conditions. The view is that our tyres travel up to 25% (5) further thanks to regrooving, i.e. 58,050 km (232,200 x 25%). The fuel savings are calculated over the distance travelled by the regrooved tyres (58,050 km) at an average consumption of 29.5 L/100 km for new tyres and 27.91 L/100 km for regrooved tyres (source: DEKRA report No. 21CPAEXT-030). 29.5 x 5.4%, i.e., a saving of 1.59 L/100 km for an articulated truck and tri-axle trailer (thus 12 tyres)

Consequently, there is a saving of 0.13 L/100 km per tyre (1.59 L/12), i.e., 0.13 L x 58,050 km/100 = 77 litres of fuel saved when driving on regrooved tyres, thus a saving of 77 litres of diesel x 3.24 kg of CO2 = 251 kg of CO2. The emissions factor of 3.24 kg of CO2 for 1 litre of diesel comes from the life cycle assessment conducted by ADEME for pure diesel.

It includes emissions during the diesel production stages (17%) and during its combustion (83%). Source: ADEME. Base Empreinte, Étude Carbone, Version 22.0.0, 02/08/2022. Thus 77 x 3.24 kg of CO2 = 251 kg of CO2.