Flat tyre: does my tractor have a punctured tyre

Flat tyre: does my tractor have a punctured tyre?

SUMMARY:

What if it wasn't a punctured tyre?

If you have been alerted by your remote inflation system or if you think you have a flat tyre, or at least one that is more deflated than normal, the first thought that may come to mind is that you have a punctured tyre. But the cause may be different.

How do you know whether you have a punctured tyre or not?

Inflate it!

Yes, this is the very first thing we recommend you do, simply because it's the one thing that will enable you to confirm one of the outcomes below:

1 - The alert given by your remote inflation system (CTIS) may have been due to a measurement error. Variations in external temperatures lead to variations in pressure. And depending on the tolerance of the sensors, this can generate an alert of a flat tyre, which may or may not be justified.

2 - There is a slight, unnoticeable drop in pressure, which is normal if you haven't adjusted your tyre pressure for a long time. And restoring the optimum pressure for your activity will prevent you from damaging the tyre while driving.

3 - You hear a continuous air leak, which confirms that there is a real problem.

In this 3rd case, where abnormal air loss is confirmed, it may be due to :

- either an airtightness problem

-

or a tyre puncture.

An airtightness problem

If it's a tightness problem, it may be due to a fault with the valve. For example, the valve cap has been lost or is no longer air-tight, or the point where the valve is attached to the rim is leaking air.

Another possibility is that, when working in the fields, soil may have infiltrated between the rim and the tyres bead causing a leak.

A third possibility is that the inner butyl liner has become porous over time and is no longer able to hold air as it used to.

A punctured tyre

A tyre puncture can happen in your activity.

It will have been affected by a cut or perforation in the tread or sidewall, or by a crack in the rim.

A punctured tractor tyre

What should you do?

At this stage, you may not yet know whether it is a tyre puncture or an airtight problem. To try and locate the leak, a simple trick is to spray soapy water on the tyre, the rim and the valve.

If, for example, you find an air leak in the valve, tightening it may be enough to solve the problem.

In other cases, it may be preferable to consult a agricultural tyre professional who will examine the tyre more closely with an expert eye and will be able to judge whether or not it can be repaired.

Here is some advice on how to avoid tyre damage in the future.

When can a tyre puncture be repaired?

In some cases, even if your tractor has a punctured tyre, a repair is possible. Depending on the type of damage it has suffered, the length and depth of the cut, and where it is located, the tyre professional will be able to tell you whether your tyre can be given a second life or not.

In other cases, repair will be impossible and replacement will be necessary.

Tyre puncture: Repairable damage

Repairable Damage

Below is a list of cases where a punctured tyre can normally be repaired.

- Cuts or aggressions to lugs, e.g. metal debris stuck in tyre.

- Cuts or aggressions on the tread.

- Small punctures on the inner side of the tyre.

- Slight cuts on the sidewall, perpendicular to the circumference

Here are some photos of repairable damage:

Repairable damage: tyre tractor example1

Repairable damage: tyre tractor example

Repairable damage: tyre tractor example3

Tyre puncture: Non-repairable damage

Non-repairable Damage

In the following cases, the tyre puncture cannot or should not be repaired.

-

For technical reasons or because repair would not be cost-effective.

-

Long, deep cuts on the inner side of the tyre.

-

Sidewall damage in a circumferential direction.

-

Damage vicinity of the bead.

-

Radial splits.

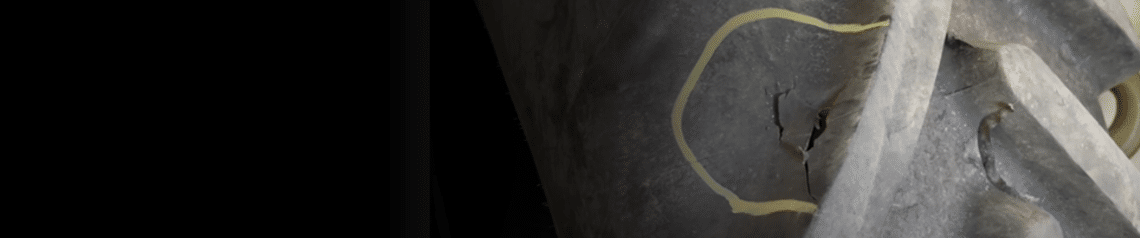

Here are some photos illustrating non-repairable damage:

Non repairable damage example1

Non repairable damage example2

Non repairable damage example3

How is a tyre puncture repaired?

In this video, an expert shows you concrete examples of repairable/non-repairable punctured tyres and demonstrates step-by-step how he carries out a repair.

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesNeed to replace a flat tyre? Find the best MICHELIN tyre for your needs.

Other articles to find out more:

Need more advice? Discover our tyre damage and wear guide