Why is tyre retreading a good option for my trucks?

Why is tyre retreading a good option for my trucks?

SUMMARY:

WHAT IS TYRE RETREADING?

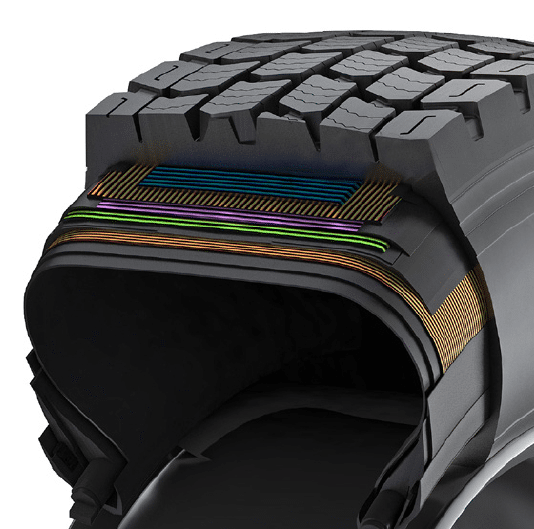

Tyre retreading is a practice that Michelin developed over the years. It consists of reusing the casing of a tyre and replacing the worn tread with a new one. Of course, for this process, MICHELIN tyres are designed from the beginning with the objective of being retreaded, with a casing strong enough to give the tyres several lives.

Did you know?

The initial ambition of the Michelin brothers was to reduce the cost of tyre use while guaranteeing safety and exceptional longevity.

It was with this in mind that tyre retreading first appeared in 1923 in the company's commercial documents.

It's a technique that is still modern 100 years later.

Why can truck tyre retreading benefit you?

When a truck tyre reaches a pronounced level of wear, it is of course possible to replace it. But retreading a tyre, rather than replacing it outright, offers considerable advantages in terms of budget, while providing performance similar to that of a new tyre.

Sentence for France, Spain, Portugal, Switzerland, Germany, Austria, BNL : In fact, a retreaded tyre is in average 40% less expensive than an equivalent new tyre(1) and allows you to drive up to 2 times more kilometres with the same casing(2). Which casing can be retreaded up to 2 times with MICHELIN Remix brand and up to 4 times with LAURENT Retread brand.

Sentence for others countries where MICHELIN remix brand is commerciliazed: In fact, a retreaded tyre is 40% less expensive than an equivalent new tyre(1) and allows you to drive up to 2 times more kilometres with the same casing(2). Which casing can be retreaded up to 2 times with MICHELIN Remix brand.

Truck tyre retreading consists of reusing the casing of a tyre and replacing the worn tread with a new one

Tyre regrooving + tyre retreading = more productivity gains!

Retreading a tyre is the third phase in the multi-life process of a MICHELIN tyre, after regrooving. By combining regrooving and retreading, you can make your tyre live several times over.

In practical terms, the same tyre can cover 25% more kilometres(3) the first time it is regrooved and reduce your fuel consumption by 5% (4) . It will be able to drive up to 100% more kilometres when first retreaded(2). Each of these two stages can then be repeated once.

So the combination of regrooving and retreading is a winning "cocktail" with clear benefits for your operating budget:

Tyre retreading is also a good choice for the planet

Not only can retreading keep your tyre running longer, it's also a healthier option for the environment.

Here are the 3 major benefits:

-

For 100 retreaded tyres, more than 11.6 tonnes(5) of CO2 are not released into the atmosphere.

-

1 retread = 50 kilos(6) less raw material compared required to manufacture of a new tyre

-

Each retreaded tyre is one less tyre to recycle!

The conditions for a successful tyre retread

Retreaded tyres are designed to offer the same levels of safety and performance of new tyres, provided the casing is of high quality, robust and designed to withstand several lifetimes.

Other conditions must be met to ensure the expected performance: the professional experience of the tyre retreader and the materials he uses must be of the highest standard.

In addition, the care and expertise of our retreaders is crucial during the selection, inspection, repair and casing stages, to ensure the quality and reliability of the finished product.

Tyre retreading requires a casing strong enough to give the tyre several lives

How to carry out a truck tyre retread in 4 simple steps

In practical terms, how do you go about retreading a truck tyre?

Step 1 - Measure your tyre wear

After the first regrooving, keep an eye on tyre wear using a tread depth gauge.

When the tread depth has reached its legal wear limit, your tyre can be demounted by your dealer and sent for retreading.

Step 2 - Contact your tyre dealer

Contact the service provider concerned to have the tyres retreaded. Used tyre casings can be handed over to the local service provider, who will organise the appropriate MICHELIN Remix retreading process.

Step 3 - Sort your tyre to send them to Michelin retread factory

Once your tyre has been demounted, the casing will be recovered and transported to a Michelin factory, where it will be checked, retreaded and returned to your service provider.

Step 4 - Optimise your truck tyre management

When you choose to entrust the management of your fleet's tyres to a local dealer, your new and retreaded tyres will be carefully looked after to optimise flow management and avoid unnecessary downtime. This also reduces the cost of storing the tyres you own.

Michelin recommends entrusting the management of your vehicles' tyres to a trusted specialist service provider. They will carry out preventive and safety inspections of your tyres and ensure that their pressure remains correct so that you can exploit their full potential... and their many lives!

Other articles to find out more:

Need more advice? Discover all MICHELIN truck tyre tips

(1) Michelin internal study performed in 2022 using a European-wide competitiveness analysis tool, comparing a new MICHELIN tyre and a MICHELIN REMIX® tyre.

(2) The mixture and tread pattern of the tread of MICHELIN Remix tyres on the whole are the same as those of new MICHELIN tyres, 90% of the rubber of MICHELIN Remix tyres is produced from the same mould and from the same materials as new MICHELIN tyres, and therefore perform equally well. Based on internal evaluations carried out by Michelin’s research and development centre and customer testimonials gathered in Europe since 2015.

(3) Compared to a worn non-regrooved MICHELIN tyre. Information based on the recommendations made by the French tyre manufacturers’ federation (TNPF) in 2019, according to which the regrooving of worn tyres increases tyre life by using all the available rubber.

(4) 5.4% save in fuel consumption: internal study carried out at the Michelin test tracks in Ladoux (France) on 5 May 2021, under DEKRA supervision (report No. 21CPAEXT-030). For the comparison between new tyres and regrooved tyres (R5 mm), two identical Volvo FH500 trucks were used, fitted with 315/70 R 22.5 MICHELIN X® Line Energy Z2 & D2 tyres and each towing a fully loaded (40 tonnes) Schmitz Cargobull trailer fitted with 385/55 R 22.5 MICHELIN X® Line Energy T tyres at identical pressures (8.5 b, 7.5 b and 9.0 b). Results may vary depending on weather conditions, road type, tyre size and driving style.

(5) The CO2 saving associated with the regrooving operation is calculated from the associated saving. In terms of material saving, a regrooved tyre can cover up to 25% more miles (compared to a new MICHELIN tyre, that has not been regrooved; for an average regrooving depth of 4 mm; information based on TNPF recommendations dating from 2013 explaining that regrooving can, when the tyre reaches the end of its wear limit, increase the tyre’s longevity by using all the available rubber). The raw material saving is calculated to be 2.3 kg of CO2* per kg of raw materials. For the example, four regrooved tyres (on a driving axle for example) equivalent to the mileage covered by one new tyre (4 x 25%), or 70 kg of raw materials, the average stated weight of a new tyre, or 161 kg of CO2. * Equivalence between CO2 and a litre of fuel or kilogram of raw material is calculated in this way: the emissions factor of 3.24 kg of CO2 for 1 litre of diesel comes from the life cycle assessment conducted by ADEME for pure diesel. It includes emissions during the diesel production stages (17%) and during its combustion (83%). Source: ADEME, Study «Well to wheel - JEC», v4, july 2014. The emissions factor of 2.3 kg of CO2for 1 kg of tyre comes from the life cycle assessment calculations for production of a tyre cradle to gate), conducted internally by Michelin using the calculation rules developed by the tyre manufacturing profession (TIP). It includes stages including extraction of raw materials, transportation, manufacturing, and distribution. Source: UL Environment Standard, «Product Category Rules for preparing an Environmental Product Declaration for the product category: Tires», v3.05, february 2022.

(6) In terms of material savings, the average weight of a new MICHELIN tyre is 70 kg*. The weight of a tyre ready to be retreaded weighs 50 kg** on average.

*Internal study based on the MICHELIN truck tyre sizes most sold on the European market: 315/80 R 22.5, 315/70 R 22.5 and 385/65 R 22.5.

**According to a TNPF publication from 2023: “retreading, which, by reusing the casing that represents approximately 70% of a tyre’s weight” (sic). As a result, 70% of 70 kg = approximately 50 kg.