How to check tyre tread depth?

How to optimise HGV tyre tread depth

The safety of your HGVs relies heavily on the condition of their tyres, particularly the depth of their tread. This parameter is much more than just a question of performance; it is a legal requirement that you must strictly follow to guarantee both the safety and regulatory compliance of your operations.

SUMMARY

What is tyre tread depth?

Tyre tread is the rubber part of your tyres that comes into direct contact with the road. Its depth is essential because it directly influences the tyre's grip on different surfaces and in different weather conditions. Insufficient tread depth can increase the risk of aquaplaning, loss of control and punctures.

How much tread is there on a new tyre?

Tyre tread depth on our HGV tyres usually lies around 15 mm, depending on the specific model of tyre and its design for different uses (long distance, regional, urban, off-road, etc.).

Truck tyres designed for winter conditions or for specific uses such as off-roading may have an even greater tread depth to provide a better grip.

MICHELIN HGV tyre

What is the minimum legal tyre tread depth?

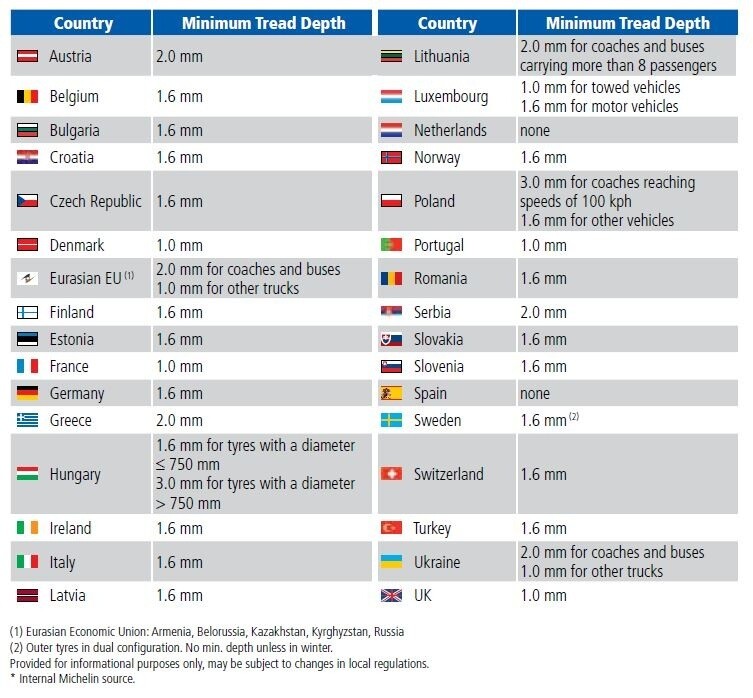

As a fleet manager, it is crucial that you are aware of the legal tyre tread depth limits. In France, for example, the minimum limit is 1.0 millimetre for vehicles weighing more than 3.5t and 1.6 millimetre for vehicles weighing less than 3.5t. Other countries, such as Austria and Greece, require a higher minimum depth (of 2 mm).

Knowing the legislation in force is essential to avoid penalties and ensure the safe operation of your fleet. Find out about the legal limits of the countries in which your trucks operate.

Discover the legal limits in the main European countries:

Picto capture page 10 wear by country Help and Advice

table with tyre wear legislation in europe

Tyre tread depth: financial and environmental implications

Tread depth is not just a matter of legal compliance, it also has a direct impact on fuel consumption: removing a tyre too early means a loss of money, since fuel consumption decreases as the tyre wears. It also means more waste, which has an impact on the environment. To optimise your fleet's operating costs and limit your environmental impact, make sure you maintain your tyres until the legal wear limit is reached.

How to check tyre tread depth?

To check your tyre tread depth, you can use a tread depth gauge, which is an inexpensive tool that provides the most accurate reading. Insert the gauge into the tread groove and press the shoulders flat against the tread block. Read the result indicated on the gauge.

Tyre tread depth

Best practice for preserving tread

To help you maximise the life of your tyres, here are a few recommended practices:

Regular tyre pressure checks

Correct tyre inflation pressure is essential to avoid premature wear. Make sure that all your tyres are inflated to the manufacturer's specifications. To optimise safety, tyre pressures should be checked at least once a month and before any long journey.

Tyre rotation

Rotating tyres between axles can help to distribute wear more evenly, prolonging their life, and is a relevant preventive maintenance technique for any fleet manager.

By swapping tyres between the left and right sides of the vehicle, or by turning tyres on the rim, you can not only extend the life of each tyre, but also help to maintain better vehicle stability and performance, particularly under demanding driving conditions.

-

Why is tyre rotation important for HGV?

Certain types of use can create particular wear profiles, which need to be smoothed out by tyre rotation and turning tyres on the rim. Regular rotation balances these differences in wear, which is particularly important for vehicles that travel long distances or are frequently used on uneven roads.

Tyre rotation can vary depending on the type of vehicle, tyre model and conditions of use, but a general rule is to rotate when the tyre reaches 50% wear or if an irregular wear pattern appears. Note that running your hand along the surface of the tyre is often enough to detect abnormal wear.

Visual and manual inspections

Encourage your drivers to check their tyres regularly for any signs of irregular wear or external damage. Cuts, cracks or embedded objects require immediate attention. Spotting them early can prevent a potentially costly roadside tyre failure.

Regrooving and retreading: economical and ecological solutions

Regrooving and retreading are both effective ways of extending the life of your tyres once the tread has reached the legal limit.

- The regrooving process involves removing rubber from the existing layer of base rubber to restore tread pattern depth, using a special tool.

- The retreading process involves replacing the worn tread with a new one, allowing the tyre casing to be reused.

Not only are they cost-effective practices, they also help to reduce the environmental impact of tyre waste, enabling your vehicle to potentially cover thousands of extra kilometres.

Conclusion

As a fleet manager, respecting the minimum legal tyre tread depth is essential for driver safety and vehicle performance. By taking a proactive approach to tyre maintenance and considering solutions such as regrooving and retreading, you can not only comply with regulations but also optimise your fleet operations. This will enable you to ensure maximum tyre longevity while supporting environmentally-friendly and cost-effective management of your fleet.

Other articles that may interest you:

Need more advice? Discover all MICHELIN truck tyre tips