How to adapt your combine harvester tyres to your needs

How to adapt your combine harvester tyres to meet your needs

SUMMARY:

Check the general condition of your combine harvester tyres

When you bring your combine harvester out of winter storage after several months, the very first thing to do is check the general condition of the tyres. Examine them to make sure there are no cuts or other forms of damage, nor too much wear that would make them likely to slip excessively in the field, forcing you to replace them after the harvest has started. If in doubt, do not hesitate to consult your tyre dealer.

Apply the correct tyre pressure

Tyre pressure is just as crucial for your combine harvester as it is for your other agricultural machinery. And why is that? Because on large machines like combine harvesters, each of your front tyres may have to carry up to 15 tonnes.

If the pressure is insufficient, this can lead to tyre fatigue and eventual failure. If the pressure is not sufficient for the load the casing will flex excessively which will eventually break the steel cables that give a combine tyre it's strength, leading to external (visible) or internal (non-visible) radial fractures. This is the beginning of the end of the combine harvester tyre's life, and replacing it prematurely would involve a cost that you could have avoided.

If, on the other hand, the tyre is over-inflated, it will compact the soil even more at a time (harvesting) when you are using a machine with the highest axle load.

So how do you determine the right pressure for your tyres?

The pressure must take account of the load. And to determine it, you need to gather several pieces of information and carry out a simple calculation.

Don't worry, we'll be with you every step of the way.

How do you estimate your combine harvester's load?

To begin with, we invite you to create a table like this one and fill it in with the values that will be used to estimate the total load:

FRONT (70%) | REAR (30%) | |

1- Combine harvester empty weight | … | … |

2- Picker weight | … | … |

3- Load transfer from picker | … | … |

4- Hopper weight | … | … |

5- Total weight per axle | … | … |

6- Total weight per tyre | … | … |

1 - Determining the combine harvester's empty weight

The first step is to find out the empty weight of your combine harvester. Ideally, you should weigh it, but if that's not possible, you can find this information on your combine harvester's serial number plate or in the manufacturer's manual.

Let's take a concrete example: that of a John Deere S770 combine harvester, with an empty weight of 18,900 kg.

2 - Determining the weight of the header

The weight of the header will also be taken into account when calculating the load.

Example of header weight: 3,550 kg.

As the header is at the front of the machine, this will generate an weight transfer from the rear axle to the front axle using the see-saw principle with the front axle being the pivot point of the see-saw. It will therefore be necessary to measure the impact in kilograms on the axle, taking into account the distance between the headers centre of gravity and the distance to the centre line of the front axle between the tool's centre of gravity and the centre of the axle hubs.

3 - Determining the combine harvester's offset and load transfer

As there is an offset with the cutterbar, we will calculate the load transfer. To do this, we first need to estimate the value of the offset.

To calculate the offset, we need to consider the attachment point of the picker and estimate the tool's centre of gravity. Taking as a reference a spot approximately 1 metre in front of the attachment point, we need to measure the distance between the middle of the front hub and this spot.

In our example, we measure an offset of 3.05 metres.

You also need to know the wheelbase (the distance between the centre of the rear hub and the centre of the front hub). It's usually given in the technical documentation, but you can also measure it easily.

In our example, we measure a wheelbase of 3m55.

The load offset coefficient is calculated as follows: Distance between the centre of gravity and the centre of the front hub divided by the wheelbase.

In our example: 3m05 / 3m55 = 0.86 is our load offset.

This coefficient is used to estimate the additional weight on the front axle.

We will now multiply the weight of the front tool by this coefficient:

In our example: 3,550 kg x 0.86 = 3053 kg (rounded up to 3050 kg). This means that we have a load transfer of 3050 kg.

Calculate your combine harvester's front/rear weight distribution

For the front/rear, a safe 70/30 ratio can be used, which applies to most machines: 70% front load and 30% rear load. This information can be checked with your dealer.

So to calculate the weight on the front axle, we apply a percentage of 70% to the empty weight. And for the rear axle, we apply a percentage of 30%.

Our result is

- 18,900 kg x 70% = 13,230 kg at the front

- 18,900 kg x 30% = 5,670 kg at the rear

You can now start transferring the data you have collected into the table, like this:

FRONT (70%) | REAR (30%) | |

1- Combine harvester empty weight | 13 230 kg | 5 670 kg |

2- Picker weight | 3 550 kg | - |

3- Load transfer from picker | 3 050 kg | - |

4- Hopper weight | … | … |

5- Total weight per axle | … | … |

6- Total weight per tyre | … | … |

4 - Calculating the weight of the grain in the grain tank

As for the combine harvester's grain tank, you normally know its volume. The idea is to take its capacity in litres and convert it into kilos. To do this, we recommend using a generous coefficient of 0.8.

In our example, the hopper has a capacity of 10,500 litres, so applying this coefficient would mean :

10,500 litres x 0.8 = 8,400 kg of hopper weight.

As a large part of the combine harvester's hopper is located at the front, we'll apply the same 70/30 ratio to calculate the front/rear weight distribution.

Our result is:

8,400 kg x 70% = 5,880 kg at the front.

8,400 kg x 30% = 2,520 kg at the rear.

You can add these values to the table.

5 - Calculate total front/rear weight

Now that we have all the information, all we need to do is add up the weights per front/rear column.

FRONT (70%) | REAR (30%) | |

1- Combine harvester empty weight | 13 230 kg | 5 670 kg |

2- Picker weight | 3 550 kg | - |

3- Load transfer from picker | 3 050 kg | - |

4- Hopper weight | 5 880 kg | 2 520 kg |

5- Total weight per axle | 25 710 kg | 8 190 kg |

6- Total weight per tyre | 12 855 kg | 4 095 kg |

In our example, the total weight of the front axle is 25,710 kg.

To find out the weight per tyre, we simply divided this number by 2: 25,710 kg / 2 = 12,855 kg per front tyre.

Same calculation for the rear:

Total rear axle: 8,190 kg, 8,190 kg / 2 = 4,095 kg per rear tyre.

Should consumables be taken into account?

Consumables such as hydrocarbons and fuel represent a weight that is sometimes included in the empty vehicle weight, which is available in the manufacturer's technical data sheet. Given that we're working on an estimate here, we're not aiming for extreme accuracy. Our focus is on the main loads to determine the total weight.

Identify the correct tyre pressures for your combine harvester

Once you have the weight per tyre, simply refer to the manufacturer's documentation to identify the correct front and rear tyre pressure. You can download Michelin's documentation here.

In our example, the tyres are MICHELIN Cerexbib 2.

The technical documentation for this tyre shows a table with pressures, loads and speeds. These three data are closely linked (to find out more, read our article on "How to avoid overloading tyres").

Here's how it works:

For our combine harvester, we estimated a total load of 12,855 kg per front tyre.

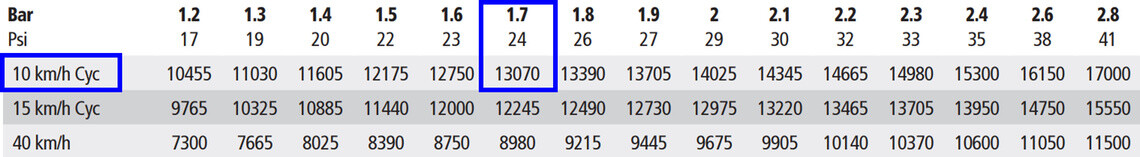

In the MICHELIN Cerexbib 2 tyre table below, we can see that if we don't intend to exceed a speed of 10 km/h, we can carry up to 13,070 kg with a pressure of 1.7 bar.

This is the pressure we should apply to our 38" front tyres, for optimum performance.

MICHELIN Cerexbib 2 tyre

VF 900/60R38 CFO+ 193A8 TL

MICHELIN Cerexbib 2 front pressure

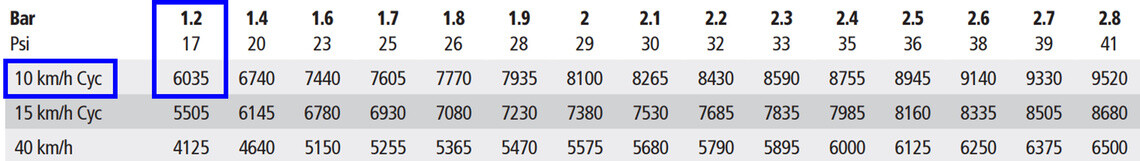

For the rear, the estimated load per tyre was 4,095 kg. Referring to the table for our MICHELIN Cerexbib 2 rear tyres, we can see that the pressure of 1.2 bar allows us to carry a load of up to 6,035 kg at a maximum speed of 10 km/h.

MICHELIN Cerexbib 2 tyre

VF 620/70R26 CFO+ 173A8 TL

MICHELIN Cerexbib 2 rear pressure

Our front/rear pressures are therefore adapted for our combine harvester.

identify the correct tyre pressures for your combine harvester

The special case of sloping ground

If there is a slope in your fields, your combine harvester will not be completely horizontal and this will mean a transfer of load from one side to the other. In this case, we will increase the pressures slightly to protect the tyre. The method of increasing pressure is shown at the end of the Michelin technical documentation

In other cases, stick to the recommended pressures

The flat spotting phenomenon

As your combine harvester has not been driven for a long period, your tyres may have sagged a little due to the natural loss of air over time. In this case, "flat spotting" may have occurred. Instead of retaining its round shape, the tyre has flattened slightly on the part in contact with the ground. This is nothing to worry about.

During the first few laps, you will feel a few vibrations until the tyres return to their normal shape. This "flat spotting" phenomenon will dissipate in a short time.

Need high-performance tyres for harvesting?

Discover our combine harvester tyres:

Other articles to find out more:

Need more advice? Discover our tyre maintenance and caring guide