When and how to check your truck tyre pressure?

When and how to check your truck tyre pressure?

SUMMARY:

The risks of incorrect truck tyre pressure

Neglecting tyre maintenance can lead to major problems. Here's why:

- When tyres are under-inflated, they generate more heat, which weakens the tyre's structure. This can cause sudden blowouts, resulting in dangerous situations for your drivers and other road users, or simply reduce the longevity of the tyres and imply premature replacement.

- Over-inflation, on the other hand, makes tyres more susceptible to wear and tear. This reduces traction, particularly in poor weather conditions and puts your fleet at risk of accidents, delays and costly repairs.

- What's more, incorrect truck tyre pressure also impacts fuel consumption. Under-inflated tyres increase rolling resistance, meaning your trucks will use more fuel to cover the same distance. This not only adds unnecessary costs but also shortens the lifespan of the tyres, resulting in more frequent replacements.

The impact of incorrect tyre pressure in a few statistics

Criteria | Longevity and wear pattern | Fuel consumption |

-20% pressure | -20% tyre life(1) | Fuel consumption up +1.7%(1) |

Pressure of -1.5 bar | tyre life of -40,000 km(2) | Fuel consumption of 0.6l/100 km(3) |

By ensuring the correct truck tyre pressure, you can prevent these issues, improve safety and reduce operating costs for your fleet.

The benefits of regular tyre pressure maintenance

Regular maintenance of your fleet's truck tyre pressure brings several key benefits, especially for fleet safety:

- Properly inflated tyres ensure that vehicles remain stable on the road, even in harsh driving conditions. This means fewer risks of blowouts and tyre-related accidents. Shorter braking distances will also allow your drivers to have better control in emergencies, reducing the risk of collisions.

- Financially, maintaining the right tyre pressure can save you a significant amount of money:

- Tyres that are kept at the correct pressure wear more evenly, extending their lifespan. This leads to fewer tyre replacements and lower overall maintenance costs.

- Furthermore, well-inflated tyres reduce fuel consumption because they reduce rolling resistance, making your vehicles more fuel-efficient. With the rising cost of fuel, these savings can make a big difference in your fleet’s profitability and help you optimise your TCO (Total Cost of Ownership).

Correct truck tyre pressure optimises fuel consumption

Male worker in uniform takes a gun at a gas station, fuel filling. Petrol fueling, gasoline or diesel refuel service

- Finally, regularly maintaining truck tyre pressure helps to reduce your fleet’s environmental footprint. By using less fuel and extending the lifespan of your tyres, you will contribute to a more eco-friendly operation, which is increasingly important for businesses concerned with sustainability.

Practical tips for managing truck tyre pressure

Let's take a look at what our experts recommend for maintaining the correct truck tyre pressure.

Make sure regular checks are carried out

Ideally, truck tyre pressure should be checked at least once a month, and always when the tyres are cold. Cold tyre readings are more accurate because the pressure naturally increases when tyres are hot.

Make sure your drivers are educated on this process and encourage them to visually inspect tyres before each journey. This will help catch any potential issues, such as punctures or uneven wear, early. Regular inspections are also advised to check for structural damage, such as cuts or sidewall abrasions.

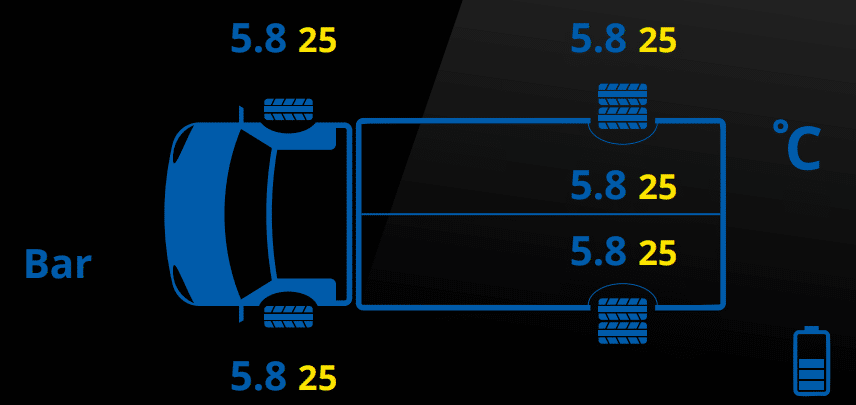

The driver's inspection should start with the front left tyre and go clockwise around the truck, as shown in the illustration:

Truck tyre inspection and pressure check

When performing truck tyre pressure checks, always use a properly calibrated pressure gauge to ensure the readings are accurate. Tyre gauges can become less reliable over time, especially if they are not handled carefully.

For new or repaired tyres, we recommend inflating them inside a specialised inflation cage. This provides an extra layer of protection in case the tyre malfunctions during the process. If a cage is not available, you must stand well away from the tyre while it is being inflated.

It is crucial to never stay in front of the sidewalls, as they are the most vulnerable part of the tyre. Michelin advises using an inflation hose that is at least 3 metres long and that you face the tread during the process. By following this safety procedure, you minimise the risk of injury due to unexpected tyre failures.

Install a TPMS

In addition to manual checks, installing a Tyre Pressure Monitoring System (TPMS) is highly recommended. TPMS continuously monitors tyre pressure and alerts you in real-time if there are any abnormalities.

This system is particularly useful for long-haul routes, where tyre issues may not be noticed until it's too late. A TPMS can prevent breakdowns, keep your vehicles on the road, and ensure that your drivers are aware of any potential problems before they cause serious delays or accidents.

Screen of truck tire pressure monitoring system (TPMS)

Maximising fleet performance over the long term

By consistently managing truck tyre pressure, you will gain long-term benefits that can greatly improve your fleet’s performance.

Reduce tyre-related accidents

This is the first and most significant benefit of properly maintained pressure. It provides better vehicle stability, which enhances control and reduces the risk of blowouts. This ensures your drivers are safer on the road, and it also protects other road users from potential accidents caused by tyre failures.

Optimise the lifespan of your tyres

Maintaining the correct pressure optimises the lifespan of your tyres, resulting in fewer replacements and lower operational costs.

Optimise fuel consumption

With the correct truck tyre pressure, fuel consumption will also decrease, allowing you to save money on fuel expenses. Over time, these savings add up and contribute to the overall efficiency and profitability of your fleet.

Reduce emergency stops

By keeping your tyres in optimal condition, you’ll reduce the likelihood of emergency stops or breakdowns, which means fewer delays and more timely deliveries for your customers.

Reduce carbon footprint

Finally, a well-maintained fleet is an eco-friendly fleet. Reduced fuel consumption means a smaller carbon footprint, and fewer tyres needing replacement leads to less waste.

By following best practices for truck tyre pressure, you can ensure that your fleet operates smoothly, safely, and sustainably, which will benefit both your business and the environment.

Check out these other articles on the same subject:

Need more advice? Discover all MICHELIN truck tyre tips

(1) Source: MICHELIN internal analysis

(2) For a recommended pressure of 8 bar and an average mileage of 200,000 km (with a recommended truck tyre pressure of 9 bar: -1.5 bar gives -10% mileage).

(3) On a 5-axle road unit in motorway use with recommended pressures of between 8 and 9 bar.