post trickntruck tyre maintenance herobanner

Everybody knows that a truck’s tyres need to be changed from time to time. But there’s more to their maintenance than that. From pressure checks to regrooving to wheel alignment, let’s detail every aspect of tyre maintenance with one of Michelin’s professional trainers.

post trickntruck tyre maintenance portrait

Did you know that in addition to selling tyres, Michelin provides training to its customers on how to use and get the best from them?

In fact, the company runs training centres across Europe to do just that, catering to two main audiences:

- the dealers, who sell its tyres and always need up-to-date information about its products;

- and customers, such as transport companies who have to always stay on top of their fleet maintenance.

The idea? To raise awareness about the huge impact of taking good care of your tyres in terms of fuel efficiency, safety, saving money and keeping vehicles in good condition.

We sat down with Edouard Fadel, a trainer at Michelin’s headquarters in Clermont-Ferrand, France, to discuss the five main aspects of tyre maintenance.

Here is what he had to say.

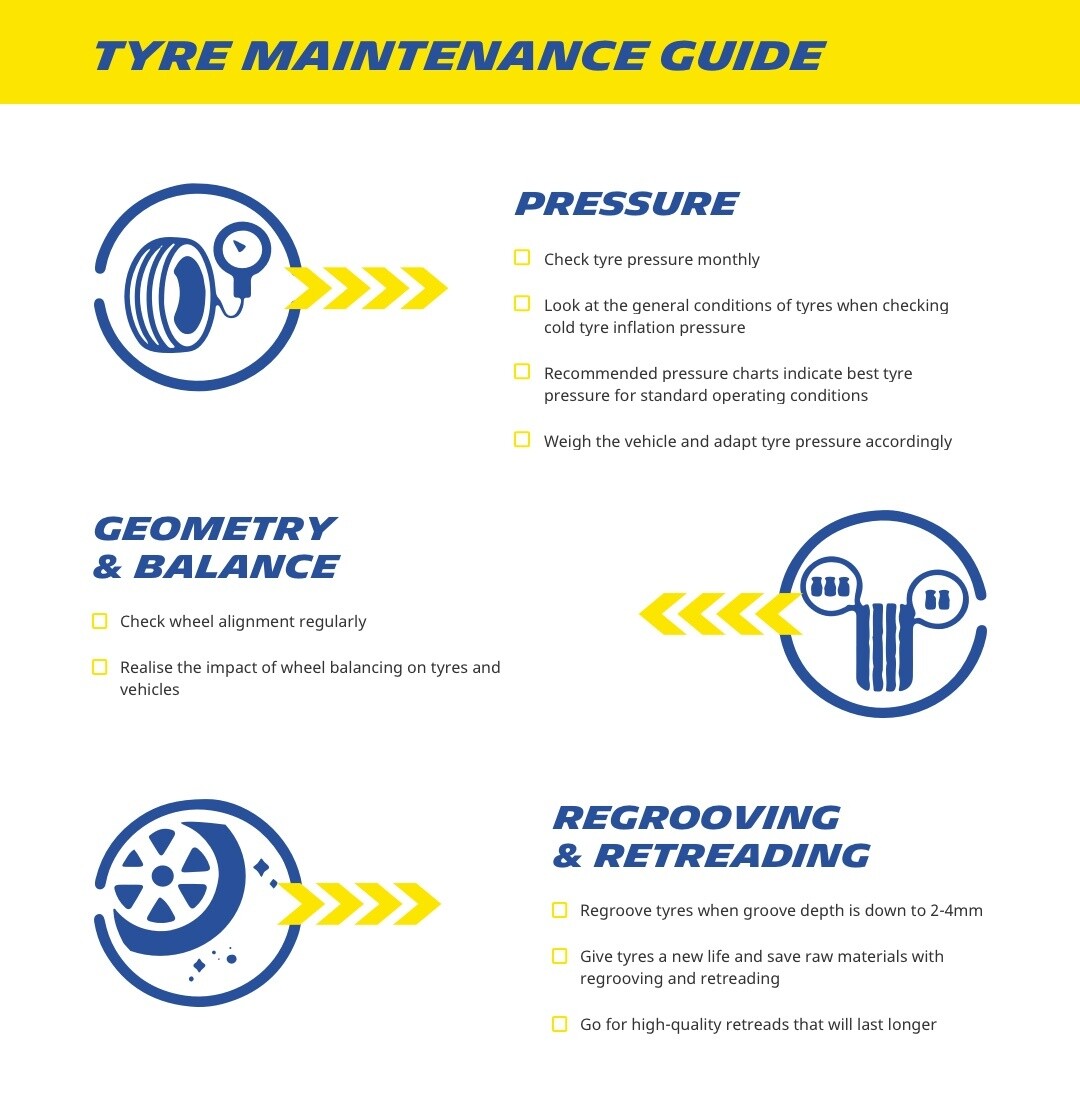

1. Pressure

Ideally, tyre pressure should be checked once a month on cold tyres, because all tyres slowly lose pressure, even those that are never checked. Also, checking the pressure is a good opportunity to take a look at the general state of your tyres.

People often don’t realise that commercial vehicle tyres account for roughly one third of a vehicle’s fuel consumption. If your tyres are poorly inflated, you’ll burn more fuel: our internal studies show that for every 1.5 bar of under-inflation you consume 1% more fuel1. It’s also bad for tyre longevity, because they wear out more quickly. On the other hand, overinflating is bad too: it also reduces tyre longevity and impacts safety. Overinflation reduces the contact surface between the tyre and the road surface and also makes the tyre more susceptible to accidental damage.

2. Regrooving

Regrooving involves removing rubber from the layer of existing rubber to restore tread pattern depth. There are many advantages to doing this: fuel savings of up to 2L per 100km, extending the tyres mileage potential by up to +25% and improved safety thanks to better adherence2.

Regrooving is also about giving tyres a second life, which is good financially, but also for the planet: when you think that a tyre casing weighs between 50 and 70kg, every time you regroove a worn tyre instead of throwing it out, you save that much raw material.

When to regroove a tyre depends how you use the vehicle and what type of terrain it rolls on. It’s a matter of tyre wear, not distance travelled or time passed. Usually we suggest it is carried out when the remaining tread depth is between 2 and 4mm.

3. Geometry Alignment

Adjusting axle geometry or alignment consists in checking that a vehicle’s wheels are property aligned to avoid excessive tyre wear. Did you know that a 1mm mis-alignment can reduce your tyres’ longevity by approximately 7%*? Not only that, but it will also increase your fuel consumption because the tyres scrub against the road surface when rolling.

Verifying your wheel alignment is easy: gently rub your hand radially across the surface of the tyre’s tread; if you feel any resistance in one direction or another, it’s an indication that your wheel alignment should be checked. There’s no set rule as to how often you should do this: let’s just say alignment should be checked as part of the vehicle maintenance schedule.

4. Wheel balancing

When you manufacture wheels and tyres, there are always going to be slight imperfections in weight distribution, because of welds and such, and these change over time, because of wear and accidental damage.

Balancing is good for the driver’s comfort because it reduces vibrations. It is also important to ensure that tyres are correctly balanced, as this plays a part in high tyre mileage performance and protects the mechanical parts from premature wear.

If balancing is required, Michelin recommends dynamic balancing, using weights applied to the wheel.

5. Retreading

After regrooving, retreading represents a tyre’s third life. Retreading means renewing the tyre’s tread, which is the rubber that’s in contact with the road. This is done with a curing process that vulcanises new rubber to the casing, so that the retreaded tyre offers performance similar to that of a new tyre. Plus, a retreaded tyre can also be regrooved to make it last even longer.

Retreaded tyres cost around 30-40% less than new ones with longevity similar to that of a new tyre, provided they’ve had a high quality retread. Such is the case for Remix tyres, the official brand of Michelin retreads, that offer the same performances as new ones.

Want to know more? Go to the Michelin website to download a document containing tyre maintenance tips from one of our experts, as well as the list of our training centres across Europe.

1 Internal study carried out by Michelin valid for 9 bar pressure.

2 Internal study carried out by Michelin valid for a complete set (truck and trailer).

3 All figures and values indicated by Edouard Fadel on 19 April 2021, based on Michelin internal studies.

Tyre maintenance guide

post trickntruck tyre maintenance memo

Interested in receiving some tyre training?

Michelin runs training centres in:

Click to reach out to them.

post trickntruck tyre maintenance photo

gettyimages 930571046

car going fast on a road by night