wave5 tyre maintenance header

Tyre maintenance is an important factor when it comes to your fleet. It not only improves safety, reliability and the technical condition of your vans, but it can benefit your bottom line if managed in the right way.

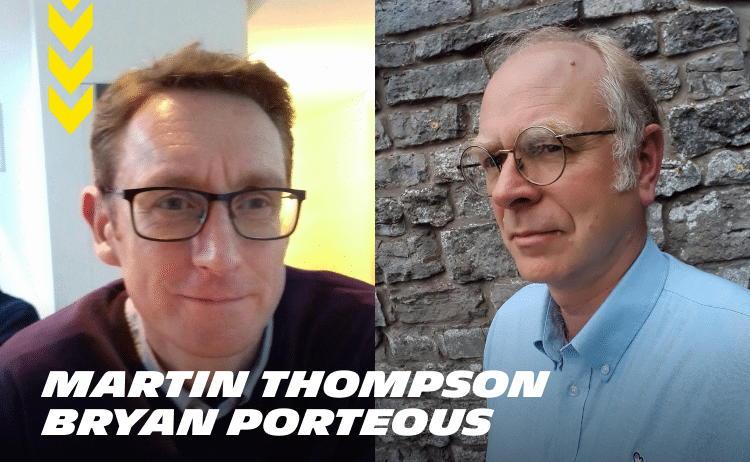

Martin Thompson, Michelin Segment Manager for the UK and Ireland and Brian Porteous, Michelin Technical Manager, share 4 action-based tips.

gettyimages 1270362497

Team of Big rig semi truck with dry van semi trailer and compact cargo mini van driving side by side on the multiline highway road working hard together for timely delivery

Van fleet operators should monitor the condition of their van tyres regularly in order to protect their investment and to predict when they will need to maintain or replace them.

Whether your van is used for deliveries, as an Ambulance, by tradespeople or any number of other services, chances are that your tyres are working in tough conditions on a daily basis. Tight roads, impacts and shocks, curbside parking, rough terrain, stop-and-go driving ౼ van tyres often have a harder life than most other types of tyre rolling on clear, open roads. So how can you extend the life of your van tyres?

wave5 tyre maintenance img1

Martin Thompson, Michelin Segment Manager for the UK and Ireland & Brian Porteous, Michelin Technical Manager.

1. Choose the right tyre for your van

First you need the correct load capacity and dimension to work properly with your vehicle and comply with regulations. That means that the tyre needs to be ready to carry the right load, be fitted to the correct wheel in good condition, and be the right size for the vehicle. Damage resistance is also a key indicator, as are whole life costs and on road performance ౼ so keep an eye out for robust sidewall protection, effective tread patterns, all-season performance, low rolling resistance and good wet and dry grip. “You need to apply the same logic to tyre choice as you do to vehicle choice,” says Porteous. “Ask yourself, what will it be used for? Where will it be driven? What will it carry and when? Once you’ve answered those questions, choose your tyre accordingly.”

tip0

Rolling resistance can impact your fuel consumption and wet grip.

This information is visible on the tyre label making it easier to choose wisely.

2. Monitor tyres regularly

Maximising uptime is a major challenge for fleets ౼ after all, downtime very quickly translates into loss of revenue. Busy drivers and owners tend to forego regular checks in favour of speedy deliveries. But taking the time to spot problems early on can yield substantial gains. For example, a stone or nail forced into your tyre, unchecked, can eventually cause a loss of pressure leading to a roadside breakdown or even an incident whilst driving. Not only might you incur emergency repair costs, but you might lose a load of frozen food or miss an urgent delivery. Instead, Thompson and Porteous recommend daily visual checks to verify the condition of all four tyres, and weekly physical tyre pressure checks.

Use the inflation pressures prescribed by the van manufacturer for the loads you carry and check tyre pressures with a good quality pressure gauge when the tyres are cold to make sure that the pressures you set are accurate. Regular checks mean that you build a picture of what is normal for your vehicle. If anything changes, you can spot it quickly and act before it develops into an emergency. The five minutes you spend doing this each day could save time and money in the long run!

tip0

Instead of checking tyres at the start of a day, have your drivers do a check at the end of their day౼ they’ll be less in a hurry and repairs can be done overnight, leaving the van ready to hit the road in the morning!

wave5 tyre maintenance img2

3. Keep a spare on hand

The majority of fleets today opt to forego carrying a spare tyre in the vehicle in favour of higher payloads. If you’re having a hard time choosing between carrying a spare or not, a good middle ground is to keep spare tyres in the depot. This allows you to maximise payload while also having a backup at the ready. If you plan to store spares in the depot, be sure to check their pressures regularly ౼ at least once a week as tyres will slowly lose pressure over time ౼ and store tyres in a clean, dry and cool environment to avoid damage.

tip0

If you choose to run without a spare, it is all the more important to keep up with regular vehicle checks!

4. Change your tyres the right way

Ideally, all four tyres should be changed at the same time. However as front and rear tyres wear at different rates, this may not always be possible. New tyres should always be fit to the rear and worn rear tyres moved to the front ౼ this maintains vehicle stability and ensures that handling characteristics will be similar to those to which the driver is accustomed. It also keeps the average age of tyres on your vehicle lower and makes sure you get all the value out of the tyres before changing.

tip0

When moving tyres from one axle to another, pressure should always be adjusted to suit the new positions.

Interview by Martin Thompson and Brian Porteous conducted on 5 April 2022

gettyimages 930571046

car going fast on a road by night