00 header what you need to know when adding electric trucks to your fleet

Evolving EU regulations and expanding low emission and zero emission zones are driving hauliers and passenger transport fleets to invest in the EV truck market. Running electric trucks requires more than just switching energy sources. Michelin’s latest white paper, ‘Electric Trucks and Buses: Rolling into the Future Together’, provides fleet managers with expert insights on the impact of switching to electric, as well as the associated operating costs.

download our white paper about electric trucks for expert insights

EV Market: What’s behind the surge in electric vehicles?

Rapidly expanding, the electric truck and bus market is driven by a greater number of environmental regulations that are also more rigorous, a growing demand for sustainable transport solutions, advancements in battery technology and new vehicle architectures. To reduce carbon footprints in the freight and passenger transport sectors, electric trucks and buses must offer competitive range, payload capacity and efficiency.

Electric Trucks: What You Need to Know

Of the types of electric trucks and buses that are currently either in series production, or under development, below are the two that are showing the most promise:

Battery electric vehicles (BEV), where electricity is stored in a battery. In terms of adoption, 30% of new trucks delivered into service in Europe are projected to be electric by 2030, and 55% of new buses.1

Fuel cell electric vehicles (FCEV) are an encouraging alternative but aren’t yet ready for full-scale deployment. They generate electricity through hydrogen stored in on-board tanks.

02 battery electric vehicle bev vs fuel cell electric vehicle fcev

A growing charging infrastructure

Currently, drivers have more charging stations available to them in some countries (i.e. the Netherlands, Germany, France) than others. Planning routes within range means that most trucks can be charged on-site at night - or topped up during a 45-minute break. The Alternative Fuels Infrastructure Regulation has deployment targets that must be met between 2025 and 2030, with charging stations every 60 or 100 km along most important road networks between major cities.2

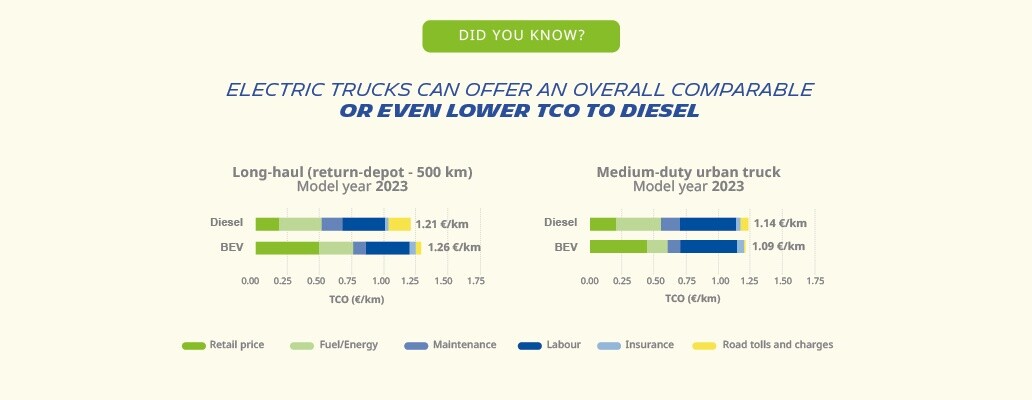

Minimal TCO impact

The good news is that with electric trucks, your total cost of ownership (TCO) is minimally impacted compared to an internal combustion engine vehicle. The difference is estimated to be no more than five euro cents per kilometre. For medium duty urban electric truck fleets, the difference is in favour of electric vehicles. For long-haul transport, it’s in favour of internal combustion engine vehicles, but the gap is narrowing quickly. 3

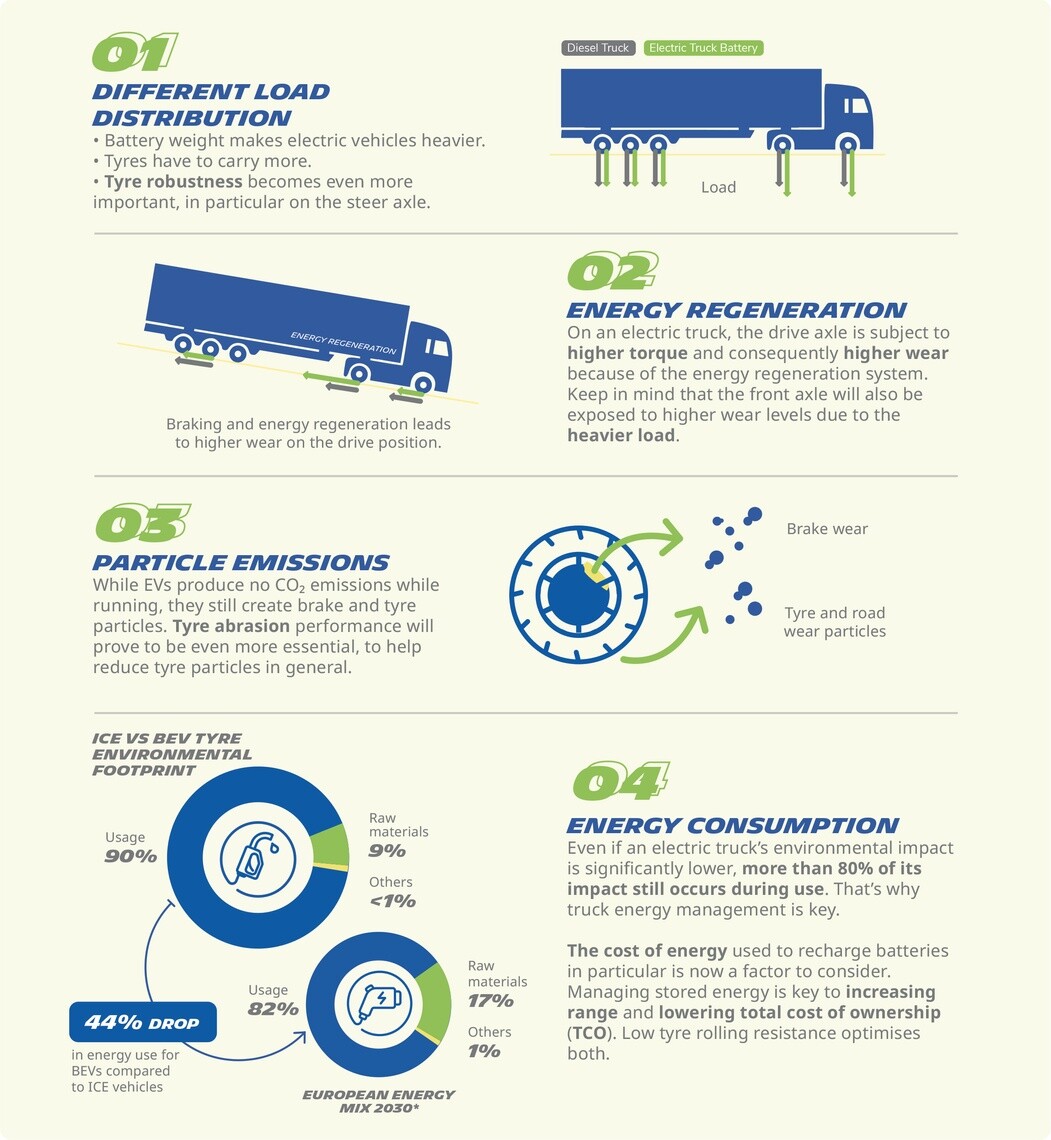

EV suitable tyres work harder

What is an electric truck’s impact on tyres? The weight of the batteries changes the load distribution. The steer and drive axles carry more and wear more. Braking and energy regeneration create more torque on the drive axle, which means tyres wear faster. Faster wear increases particle emissions.

Furthermore, managing an electric truck’s stored energy is key to optimising range and TCO, therefore optimising energy costs. This helps to make e-trucks an economically viable solution. Low rolling resistance contributes strongly to both reducing tyre wear and optimising energy costs.

03 electric trucks can offer an overall comparable or even lower tco to diesel

Only premium tyres will do for electric trucks; here is why

When it comes to maximising electric truck and bus performance, tyres need to be exceptionally robust and durable, with both low rolling resistance and low particle emissions. In other words, a suitable tyre must have it all. Michelin has a long track record of developing innovative tyres that meet these criteria for optimum truck and bus performance, as well as fleet managers’ criteria of safety, durability and a low TCO.

For an electric truck compared to a vehicle with an internal combustion engine, a tyre must be robust enough to carry the extra load capacity (up to LI 2584). Higher mileage potential is also needed to counter the wear caused by the additional load and torque.

EV suitable tyres need to have lower road and tyre wear particle emissions, to ensure compliance with Euro 7 regulations. Good traction and braking performance are essential to safety. Electric trucks make less noise, magnifying that made by their tyres, so tyres must be fine-tuned for ultra-quiet running. Critically for electric trucks, suitable tyres need to provide longer range. This is in part possible thanks to low rolling resistance.

04 why premium tyres are the only suitable choice for electric trucks

High performance electric trucks require high performance tyres

A big focus on this next generation of MICHELIN X® Multi Energy was to ensure the tyres were suitable to the specific performance requirements of electric truck fleets, including load and torque,’ François Le Hen, Product Marketing Director at Michelin, summarises. It was also important ‘to reduce operating costs for fleet managers and contribute to their environmental transition,’ he continues, ‘while still providing high levels of safety.

In keeping with Michelin’s sustainability commitment, the MICHELIN X® Multi Energy 2 was created, and uses 1.9 kilograms less raw materials during production.5 The casing is still incredibly robust,’ comments Frédéric Domprobst, Predevelopment Truck Tyre Designer. ‘We made sure it’s fit for the higher load capacity on the steer axle. It will also offer high acceptance rates for retreading, and there’s a marked improvement in rolling resistance. For electric truck fleets, that’s critical.

Damien Bardin, Development Truck Tyre Designer, sums it up best, ‘This new generation tyre really hits a sweet spot in terms of high-level performance across all key criteria for electric trucks and buses.

Electric trucks FAQ

Currently, these electric vehicles have a range that reaches approximately 300 kilometres in urban centres, and 400 to 550 kilometres for primarily regional missions, subject to external factors including driving style and weather.6 This is sufficient for many vehicles operating on ’back-to-base’ work, before being charged at the depot overnight. Recharging can also take place during a rest stop. Tyres that offer low rolling resistance can help extend range.

In terms of tailpipe emissions, electric trucks and buses are considered zero emission vehicles. Their on-board electric power source releases no toxic pollutants into the atmosphere. To be considered true zero emission trucks, the electricity used to charge the battery should be from a renewable energy source, and tyres and brakes should release no particles. Having said that, when the full lifecycle of electric trucks and buses is accounted for, from manufacture to recycling, their emissions are anywhere from 43 to 64% lower than for an internal combustion engine vehicle’s full lifecycle7. So yes, electric trucks and buses are moving in the right direction.

Click on the button below to download your free white paper !

1. S&P Global; 2023 data set; Green rules scenario for trucks.

2. European Council. Alternative Fuels Infrastructure

3. The International Council on Clean Transportation (ICCT)

https://theicct.org/publication/total-cost-ownership-trucks-europe-nov23/

4. Load Index: 315/70R22.5 MICHELIN X® Multi Energy Z2 vs 315/70R22.5 MICHELIN X® Multi Energy Z: +2 LI, 158/150 L (154/150 M) vs 156/150 L, 8.5 t vs 8 t / +500 kg by axle; 315/70R22.5 MICHELIN X® Multi Energy D2 vs 315/70R22.5 MICHELIN X® Multi Energy D: +2 LI, 156/150 L (154/150 M) vs 154/150 L; 315/80R22.5 MICHELIN X® Multi Energy Z2 vs 315/80R22.5 MICHELIN X® Multi Energy Z: +2 LI, 158/150L (154/150M) vs 156/150L (154/150M), 8.5 t vs 8 t / +500 kg by axle; 315/80R22.5 MICHELIN X® Multi Energy D2 vs 315/80R22.5 MICHELIN X® Multi Energy D: iso, 156/150L (154/150M) vs 156/150L (154/150M).

5. Mass: 315/70R22.5 MICHELIN X® Multi Energy Z2 vs 315/70R22.5 MICHELIN X® Multi Energy Z: -0.5 kg; 315/70R22.5 MICHELIN X® Multi Energy D2 vs 315/70R22.5 MICHELIN X® Multi Energy D: +0.2 kg; 315/80R22.5 MICHELIN X® Multi Energy Z2 vs 315/80R22.5 MICHELIN X® Multi Energy Z: -1.9 kg; 315/80R22.5 MICHELIN X® Multi Energy D2 vs 315/80R22.5 MICHELIN X® Multi Energy D: -1.1 kg; -0.8 kg on average.

6. European Commission. Alternative Fuels Observatory

https://alternative-fuels-observatory.ec.europa.eu/consumer-portal/available-electric-vehicle-models

7. SCANIA Life Cycle Assessment

MICHELIN X® Multi Energy 2 Range product page

(1) EV range increase: MICHELIN X® Multi Energy 2 range +5% vs MICHELIN

X® Multi range (internal calculations based on rolling resistance tyre test

results & simulations)

(2) Mileage: 315/70R22.5 MICHELIN X® Multi Energy Z2: 96 vs MICHELIN X® Multi Energy Z (100), 315/70R22.5 MICHELIN X® Multi Energy D2: 91 vs MICHELIN X® Multi Energy D (100), 315/80R22.5 MICHELIN X® Multi Energy Z2: 90 vs MICHELIN X® Multi Energy Z (100), 315/80R22.5 MICHELIN X® Multi Energy D2: 96 vs MICHELIN X® Multi Energy D (100). Internal study based on simulation tool, Ladoux Research Centre, 2024. Results may vary according to the road conditions, weather conditions and driving style.

(3) Retreadability: High retreadability (highest acceptation rate in the market) and retread offer continuity for circularity (Remix X Multi Energy D2).

(4) Load Index: 315/70R22.5 MICHELIN X® Multi Energy Z2 vs 315/70R22.5 MICHELIN X® Multi Energy Z: +2 LI, 158/150 L (154/150 M) vs 156/150 L, 8.5 t vs 8 t / +500 kg by axle; 315/70R22.5 MICHELIN X® Multi Energy D2 vs 315/70R22.5 MICHELIN X® Multi Energy D: +2 LI, 156/150 L (154/150 M) vs 154/150 L; 315/80R22.5 MICHELIN X® Multi Energy Z2 vs 315/80R22.5 MICHELIN X® Multi Energy Z: +2 LI, 158/150L (154/150M) vs 156/150L(154/150M), 8.5 t vs 8 t / +500 kg by axle; 315/80R22.5 MICHELIN X® Multi Energy D2 vs 315/80R22.5 MICHELIN X® Multi Energy D: iso, 156/150L (154/150M) vs 156/150L (154/150M).

(5) 3PMSF marking: 315/70 & 80 R22.5 MICHELIN X® Multi Energy Z2 & D2: 3PMSF (3 Peak Mountain SnowFlake) marking (validated with the regulatory test R117 for grip on hard snow).

(6) Grip and traction: 315/70 & 80 R22.5 MICHELIN X® Multi Energy Z2 & D2: Long lasting grip and traction whatever the weather. Grip until the last mm, being understood as until the minimum legal tread depth (1.6 mm). Pleaserefer to the minimum legal tread depth in your country.

(7) Noise: 315/70R22.5 MICHELIN X® Multi Energy Z2 vs 315/70R22.5 MICHELIN X® Multi Energy Z: iso; 315/70R22.5 MICHELIN X® Multi Energy D2 vs 315/70R22.5 MICHELIN X® Multi Energy D: +2 dB; 315/80R22.5 MICHELIN X® Multi Energy Z2 vs 315/80R22.5 MICHELIN X® Multi Energy Z: -3 dB; 315/80R22.5 MICHELIN X® Multi Energy D2 vs 315/80R22.5 MICHELIN X® Multi Energy D: -1 dB

(8) Mass: 315/70R22.5 MICHELIN X® Multi Energy Z2 vs 315/70R22.5 MICHELIN X® Multi Energy Z: -0.5 kg; 315/70R22.5 MICHELIN X® Multi Energy D2 vs 315/70R22.5 MICHELIN X® Multi Energy D: +0.2 kg; 315/80R22.5 MICHELIN X® Multi Energy Z2 vs 315/80R22.5 MICHELIN X® Multi Energy Z: -1.9 kg; 315/80R22.5 MICHELIN X® Multi Energy D2 vs 315/80R22.5 MICHELIN X® Multi Energy D: -1.1 kg; -0.8 kg on average.

(9) Single fitment: 158, Dual fitment: 150, Speed index: L

(10) Single fitment: 156, Dual fitment: 150, Speed index: L

(11) Comparison of Load Index between 275/70R22.5 MICHELIN X® INCITY EV Z (152/149J) versus 275/70R22.5 MICHELIN X® INCITY Z (148/145J). Up to 8 tons due to the +15% load capacity as defined in ETRTO for urban usages (LI 152 for single fitment = 7,100kg + 15% = 8,165 kg on front axle)

(12) Internal measurement based on longevity test run in average real usage on fleets with 45 Electric Bus placements, from July 2020 up to now, with 50,000km at Amiens (France) and 80,000km at Eindhoven, (Netherlands) run and extrapolated with estimated longevity at 2mm, comparing 275/70 R 22.5 MICHELIN X® INCITY EV Z (152/149J) versus MICHELIN X® INCITY HLZ (150/145J) on Steer and Drive axles. Results may vary depending on the weather, type of road and driving behaviour.

(13) Internal measurements of rolling resistance of 275/70 R 22.5 MICHELIN X® INCITY EV Z, class C, in comparison with 275/70 R 22.5 MICHELIN X® INCITY XZU, class D (+13%), and in comparison, with 275/70 R 22.5 MICHELIN X® INCITY HLZ, class D (+5%).

(14) Internal Calculation based on Rolling Resistance value with TCO2Simulator Tool for the gains per bus/year on E-BUS & ICE-BUS 275/70 R 22.5 MICHELIN X® INCITY EV Z (152/149J) versus MICHELIN X® INCITY XZU (148/145J); On EV BUS: -2.8kWh/100km on average of 70 000km/year = -1,960kWh/bus/year based on Urban e-Bus configuration 4x2 & energy cost 1kWh=€0.1. Full Energy Cost 275/70 R 22.5 MICHELIN X® INCITY EV Z (152/149J) 146.67 kWh/100km versus MICHELIN X® INCITY XZU (148/145J) Full Energy Cost 149.42 kWh/100km On ICE Bus -1kg of CO2/100km on average of 70,000km/year = -280l/bus/ year based on Urban ICE-Bus configuration 4x2 and diesel cost 1l=€1. Full Energy Cost 275/70 R 22.5 MICHELIN X® INCITY EV Z (152/149J) 34.94l/100km versus MICHELIN X® INCITY XZU (148/145J) Full Energy Cost 35.33l/100km so -0.4l/100km so -280l/bus/year on average of 70,000km/year. CO2 Emissions on 275/70 R 22.5 MICHELIN X® INCITY EV Z (152/149J) 128.60g CO2/km versus MICHELIN X® INCITY XZU (148/145J) 138.90gCO2/km so -0.7ton of CO2/100km

(15) Single fitment: 152, Dual fitment: 149, Speed index: J

gettyimages 930571046

car going fast on a road by night