header the right tyre for the right terrain

Every worksite environment, whether it’s a construction site, mining business or off-road logistics operations, brings its own challenges due to difficult, and often aggressive, ground conditions. Therefore, opting for the right tyre for a specific usage is crucial.

Here, Zoran Cvijanovic, Account Manager for Civil Engineering Tyres at MICHELIN Norway, shares his tips on how to make the right choice.

portrait the right tyre for the right terrain

Zoran Cvijanovic, Account Manager for Civil Engineering Tyres at MICHELIN Norway

Before delving into the details, you must know that the dimensions of a wheel can range from 8 to 63 inches, depending on the machine you are operating. In most cases, the machine size as well as the manufacturer will determine the tyre size. However, when it comes to considering other factors, here are the top three things that you should do.

1. Think about tread pattern

The tread pattern is the geometrical pattern that defines the crown of the wheel and is composed of lugs and edges (voids). The tread is the part of the tyre that makes contact with the surface of the ground. It is therefore crucial to have the right pattern for your specific use.

The tread pattern will enhance a vehicle with traction and grip so you can accelerate, turn and brake more effectively. It also contributes to the protection against rocks, stones and other objects that may cut and puncture the tyre. The goal of the tread pattern is to address specific driving needs depending on the usage. For example wet braking, aquaplaning, dry handling, resistance and traction on snow and ice.

If you are operating machines in countries like Norway, where winter and cold weather are a reality, you might need better traction on snow and ice. This can be found on MICHELIN X SNOPLUS tyres, which are designed with many and smaller lugs. The lugs contain sipes, thin slits in the tread pattern, that improves traction on snow and ice.

The pattern is also very important when it comes to protecting your tyre from cuts that might cause separations and punctures. “For this we have a classification system for our loader and dump truck tyres. The classification ranges from L2/E2 to L5/E5” explains Zoran.

A loader operating close to the blast wall at a mine or a quarry will use L5 or L4 tyres. L4 or L3 tyres will be used when the loader is loading a crusher, away from the largest and sharpest rocks. It’s all about the harshness of the environment. The higher the number, the higher the amount of rubber in the pattern. Thus, the higher the resistance to cuts and damage.

2. Look at the load case

When choosing the right tyre, you also need to take into consideration the load and how far the loader is to operate. Is the machine used for heavy loading in a small operating radius or is it a case of “Load & Carry”. This is very important as tyres have different load capacities and carrying abilities. If a tyre that is designed for heavy loading in short distances is used for longer transport, it can for example lead to overheating, which can potentially cause a blowout.

For the larger tyres that are used on RDTs (Rigid Dump Trucks), Michelin operates with an index that is called TKPH (Tonne Kilometre Per Hour). It takes into consideration the load, distance and time that the tyre is operating under. When choosing tyres for these loaders, you should do a TKPH calculation. You take the machine set load, the distance it will travel and the time of travelling. Putting this data into a formula will give you the TKPH value and by consulting a data book, you will be able to find which tyre is suited for the case in question.

It is very important that every tyre is chosen with the correct load index or TKPH.

If the tyre is used in any way beyond its designed limits, it will generate issues and eventually fail, resulting in shortened tyre life and downtime.

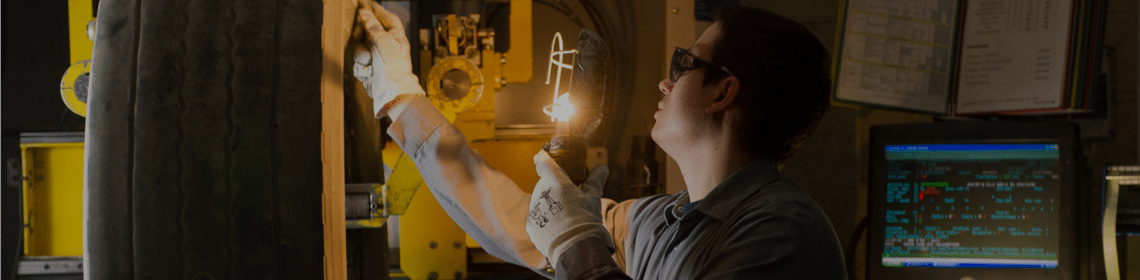

interior choosing right tyre

3. Examine the rubber compound

Like Formula 1 cars, larger RDT (Rigid Dump Trucks) tyres come with different rubber compounds. There are several compounds ranging from A4 to C. These compounds differ in hardness that makes them resistant to aggression on one side and resistant to heat on the other. An A4 tyre will demonstrate high resistance to cuts and abrasion on rough surfaces but will also have a low TKPH (Tonne Kilometre Per Hour). On the other side of the scale, there is the C compound that is for a smoother and not so abrasive surface but is high on heat resistance and has a high TKPH.

Choosing the right rubber compound is important if you want to maximise the tyre life and minimise downtime.

If you choose a tyre with a compound that is too soft and is used over its TKPH value, it will wear very quickly and have a short life. And if you choose a tyre that is too hard, it might get damaged by cuts and punctures. Both cases will result in unplanned downtime.

Thinking about Pattern, Load Case and Compound will help you when it comes to choosing the right tyres for the right usage. Occasionally you may have to adapt these rules based on the operations being performed. Therefore, Michelin continuously works closely with the different machines manufacturers and end users to ensure that your tyres are highly resistant to damage and enjoy a long service life, helping you gain in productivity for your operations.

gettyimages 930571046

car going fast on a road by night