header retread your tyres

Should you change a worn truck tyre or retread it with Michelin?

When the tyre is suitable for retreading, it’s a no-brainer. Retreading is the best choice if you want to reduce the price you pay per kilometre and have a positive impact on the environment.

Depending on your tyre’s condition, retreading can extend its useful life by leveraging the casing’s full potential – resulting in a quality retread offering the same high quality standards and on-road performance as a new tyre!

Retread your tyres with Michelin: optimisation, durability and performance

- Significant savings: Retreading truck tyres substantially reduces the cost of tyre replacement, and has a positive impact on the Total Cost of Ownership (TCO).

- A smart choice: Retreading your tyres can help to minimise the environmental footprint of your fleet, and support long-term sustainability targets.

- Equivalent performance: Retreaded tyres deliver the same performance as a set of new tyres, providing safe and dependable operation without compromising on efficiency.

Michelin retread truck tyres: unwavering quality standards

- Wet performance: Michelin retread tyres demonstrate outstanding performance on even the most challenging wet surfaces, ensuring maximum safety on the road.

- Rolling resistance: Retreaded tyres display the same impressive rolling resistance qualities as new Michelin tyres, ensuring great fuel consumption from the first to the last kilometre.

- Noise level: Retreaded tyres feature the same noise-reducing characteristics as new Michelin tyres, thereby contributing to quieter driving and reduced road noise.

4. Environmental transparency: In line with EU Regulation 2020/740, retreaded tyres’ environmentally transparent “zero impact” labelling enables users to make informed decisions about their ecological impact.

Michelin retread truck tyres: at the heart of the circular economy

Significant natural resource savings: Every time a tyre is retreaded by Michelin, it saves up to 50 kg of raw materials, which equates to a 70% saving in comparison with a new tyre.

- Actual impact on CO₂ emissions: For every 100 tyres retreaded by Michelin, five tonnes of raw materials are saved, thereby contributing to a sizeable reduction in greenhouse gas emissions.

Tyre retreading: four steps to benefit your budget and minimise environmental impact

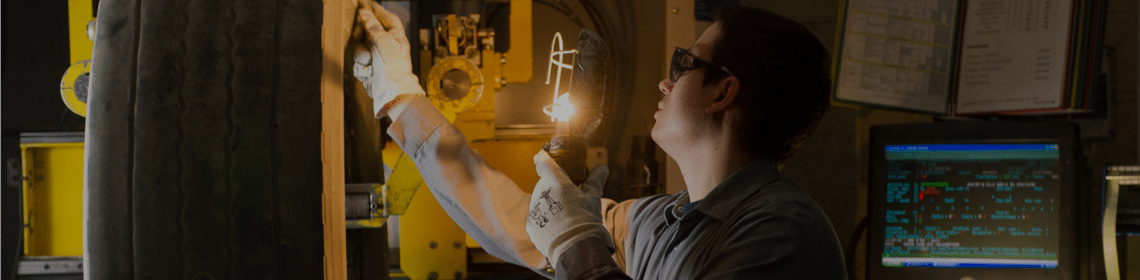

Learn how simple it is to retread tyres with our Michelin tyre retreading manager, Pierre Montel. Follow these four key steps to successfully retread your truck tyres, and discover the MICHELIN REMIX solution.

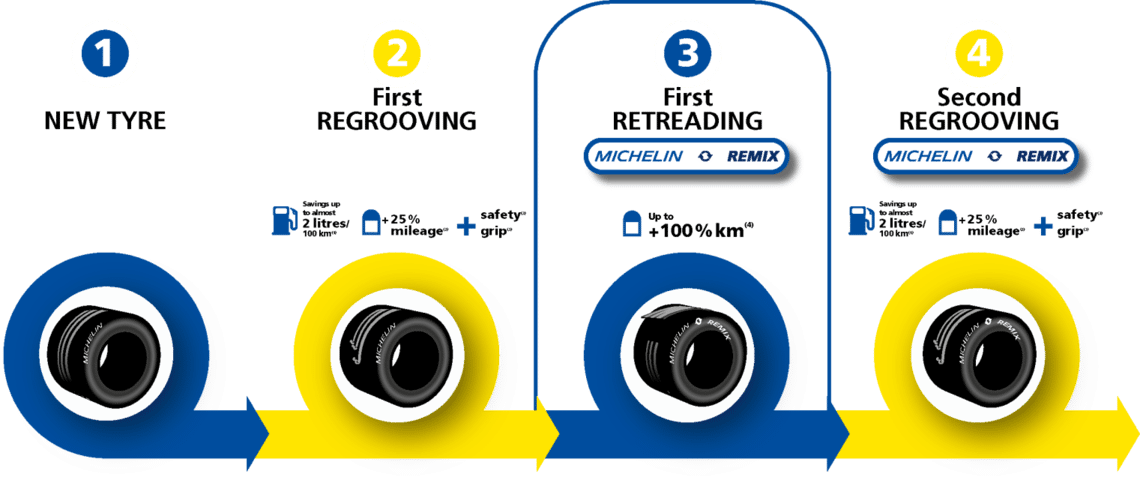

A retread tyre represents the third stage in Michelin’s multi-life process, after regrooving.

tyre life cycle regrooving michelin tyre

Measure the tyre’s wear

1-Measure the tyre’s wear

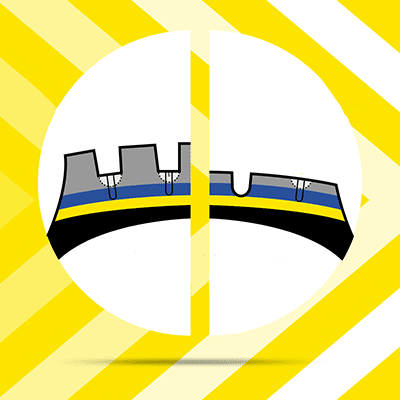

Once your new tyres have been regrooved for a second life in service, the next step is to monitor the wear using a tread depth gauge. When the remaining tread depth is between 2 and 3 mm, your tyre can be dismounted by your tyre dealer in preparation for sending it to be retreaded.

Good to know: Retreading consists of replacing the tyre’s worn tread band with a new one. All Michelin truck tyres are designed to be retreaded, sometimes several times, subject to a positive inspection of the casing. This process, developed over a century ago, enables tyres to have several lives!

Call your tyre dealer

2-Call your tyre dealer

It is the responsibility of the fleet manager or on-site workshop team to contact the service provider, as and when necessary, to have the tyres retreaded. The worn tyre casings can then be passed to the local provider, which arranges the appropriate MICHELIN REMIX retreading process.

Good to know: Once your tyre has been retreaded by Michelin, it has the same performance characteristics as a new tyre, and it can also be regrooved for a fourth life in service!

Choose to have your tyre retreaded by Michelin in Europe

3 – Choose to have your tyre retreaded by Michelin in Europe

Once your new tyre has been dismounted by the dealer of your choice, the casing will be collected and sent to a Michelin plant in Europe, where it will be checked, retreaded and then returned to your service provider. In the UK, the majority of all MICHELIN REMIX tyres are produced at the Michelin factory in Stoke-on-Trent.

During the retreading operation, both the tread and the sidewalls will be restored to as-new condition.

Good to know: In the UK, the Michelin Group’s Encore retread process is able to retread on worn MICHELIN Remix casings, and those worn casings originating from a selection of other manufacturers. One of the key benefits of the Encore process is that it allows an operator to undertake a smooth switch over to a Michelin policy from a competitor tyre brand.

illus rechapage 4

4 – Optimise the management of your tyres

When you choose to outsource your fleet’s tyre management to a local dealer, your new and retreaded tyres will be carefully managed to optimise flow management and avoid unnecessary downtime, whilst at the same time reducing the cost of any tyre stock you carry.

Michelin recommends entrusting the management of your vehicles’ tyres to a specialised service provider you can trust. A service provider will ensure that your tyre pressures are correct and take charge of preventive tyre safety inspections so that you can leverage your tyres’ full potential... and all their lives!

Good to know: Opting to give your tyres multiple lives by having them regrooved and retreaded can significantly reduce your overall TCO.

(1) 5.6% reduction in fuel consumption: an internal Michelin study carried out in Ladoux (France) in May 2021, under the supervision of DEKRA, comparing new MICHELIN X® LINETM ENERGYTM Z2 and D2 315/70 R 22.5 tyres with the same regrooved tyres (R 5 mm). Results may vary in real-use conditions and according to weather conditions, road type, tyre size and driving style.

(2) Michelin internal study in 2010 in Ladoux on a polished concrete track. Results may vary in real-use conditions and according to weather conditions, road type, tyre size and driving style.

(3) Michelin study conducted on 1 million tyres provided for Michelin Remix retreading in 2008 and 2009. The difference in the approval rate between retreaded regrooved tyres and retreaded non-regrooved tyres is below 0.2%.

(4) The tread compound and pattern of the MICHELIN Remix tyres are largely the same as those used for new MICHELIN tyres. 90% of the range of MICHELIN Remix tyres uses the same mould and the same materials as new MICHELIN tyres which may lead to up equivalent performance between MICHELIN Remix tyres and new Michelin tyres. Internal evaluations carried out by the Michelin Research and Technology Center based on customer testimonials collected in Europe since 2015.

gettyimages 930571046

car going fast on a road by night