00 trucks tyre rotation the answers to your questions

Welcome to our comprehensive FAQ section on tyre rotation and turning tyres on the rim to help fleet owners and drivers maximise the lifespan of their tyres, and at the same time, save money and enhance truck safety. Discover the insights from Antoine-Jules Sanches-Antunes, Michelin Manager Customer Engineering Support, on why these maintenance practices are essential, how to perform them and how often!

01 antoine jules sanches discuss the importance of rotating tyre and maintenance

Antoine-Jules Sanches-Antunes-Michelin Manager Customer Engineering Support

Numerous factors like load distribution, alignment and usage conditions can lead to uneven tyre damage, causing accelerated wear on certain tyres. Proactive fleet owners should regularly inspect tyres for early signs of uneven wear, such as abnormal engine behavior (i.e. noise or vibrations). Follow our advice to avoid costly and time-consuming repairs!

FAQ Summary

- 1. What is the difference between tyre rotation and turning tyres on the rim?

- 2. Why is it important to rotate truck tyres regularly?

- 3. What are the warning signs of tyre wear?

- 4. How can rotating tyres have a positive impact on TCO?

- 5. How often should I rotate my tyres?

- 6. What are the risks of not rotating my tyres?

- 7. Who can perform truck tyre rotation and turn tyres on the rim?

- 8. How can I incorporate these tyre rotation tips into my fleet's maintenance routine?

What is the difference between tyre rotation and turning tyres on the rim?

Tyre rotation is the process of changing the position of a tyre on a vehicle to even out wear and maximise performance and longevity.

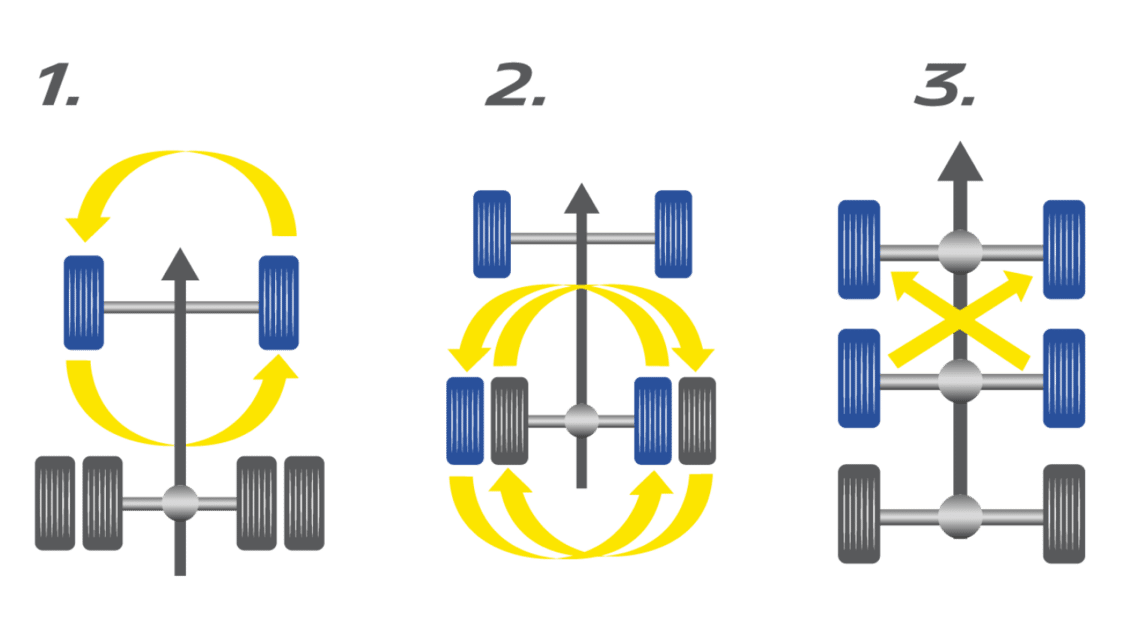

Each tyre position has recommended rotation patterns, as specified here:

02 tyre rotation diagram

- On the steering axle (1), the front left tyre tends to wear faster than the front right tyre, while the shoulder of the front right tyre can wear down more than the left.

- On the drive axle (2), both tyres on the engine's inner side exhibit more pronounced distortions on the shoulder towards the inside of the chassis.

- On a tri-axle trailer (3), the wear pattern on tyres differs for each of the three axles ౼ with very slow wear on the second axle and faster wear on the third axle.

- In certain cases, it is necessary to combine position rotation with turning tyres on the rim ౼ when a tyre is dismounted from the wheel and reinstalled in the opposite direction. That means, the side of the tyre that was previously facing inwards switches to face outwards, and vice versa. It is crucial to respect the rotation and mounting direction of a tyre and maintain the tread pattern direction in the first half of the tyre’s lifespan to optimise performance and tread wear rates.

- While this procedure can incur higher costs than tyre rotation, it ensures the casing’s suitability for retreading or regrooving!

Why is it important to rotate my truck's tyres regularly?

Like all tyre maintenance, the most important reason to regularly rotate tyres is to ensure roadholding and truck safety while driving, which also applies to tyres on cars. On top of these fundamental reasons, a consistent tyre rotation schedule can also extend the life of your tyres. By swapping the left and right tyres, you’re giving the right tyre a break and letting the left tyre “catch up” ౼ thus balancing out the wear and encouraging uniform tread depth, which translates into a longer life cycle for your tyres.

By swapping the left and right tyres, you’re giving the right tyre a break and letting the left tyre “catch up” ౼ thus balancing out the wear and encouraging uniform tread depth, which translates into a longer life cycle for your tyres.

What are the warning signs of tyre wear?

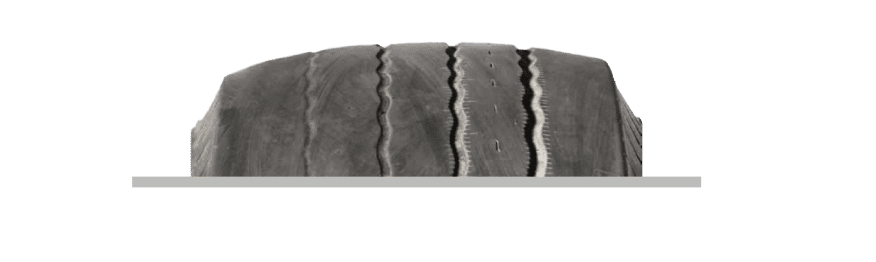

Like with all preventative maintenance practices, tyre wear should be visually monitored on a regular basis. Different wear patterns can signal different types of problems. For example:

- • Wavy patterns generally indicate that the vehicle is unbalanced and can be addressed by rotating tyres.

- • Wear on the outside or the inside of the tyre is a sign that the vehicle needs an alignment check.

- • Diagonal or scalloped patterns indicate that a tyre has uneven contact with the road, in which case you should verify the vehicle’s suspension system.

- • Wear along the centre of the tyre generally means that a tyre is overinflated and thus only the centre of the tyre touches the road.

- • On the other hand, wear on the edges indicates the opposite: your tyre is underinflated and the edges are in contact with the road.

03 signs of tyre wear

In general, wear is gradual and minimal damage doesn't necessitate replacement. However, if you notice significant asymmetric wear, such as extreme sloping on one side but not the other, the damage is likely irreparable and can lead to major safety risks. If you’re particularly observant, irregular wear can also generate noise and vibration ౼ so listen up!

How rotating tyres has a positive impact on TCO?

Each tyre wears differently, for example rear axle tyres tend to wear down much faster than middle axle tyres. Tyre rotation and turning tyres on the rim can extend the life cycle of every tyre on every truck in your fleet ౼ meaning fewer and less frequent replacements. On top of these cost saving benefits on your TCO, correctly timing relocation and replacement ensures that tyres wear more evenly, making them less prone to blowouts and other safety risks. After all, a roadside breakdown can be stressful because it will not only cost you a new tyre, but can also lead to other significant costs including the potential of vehicle damage, extended downtime, damaged goods or delivery delays that could incur penalties.

How often should I rotate my tyres?

This depends on the type of truck, position of the tyre and can vary based on use case as well. As a general rule of thumb, in order to balance wear, optimise tyre potential and minimise the risk of tyre damage, tyres should be rotated roughly halfway through their lifespan. More specifically, if the wear between tyres on a single vehicle is between 0 and 2/32 of an inch, you can hold off on rotation. However, if the difference reaches 3/32 or more, you should consider rotating tyres.

What are the risks of not rotating my tyres?

- Irregular wear on your tyres can generate several safety risks ౼ including loss of grip, increased risk of blowout, over heating (which can damage the casing and make regrooving or retreading impossible down the line), excessive fuel consumption and increased emissions. In some cases, uneven wear can even impact the rotating speeds of your tyres, potentially causing gears to grind.

- Optimise your heavy-duty tyre management with the MICHELIN MyTechXpert app.

- Download now to access recommendations, technical specifications, and much more!

Who can perform truck tyre rotation and turn tyres on the rim?

While it is possible to handle these repairs on your own, it is highly recommended to schedule an appointment with your tyre service provider to carry out potential repairs.

How can I incorporate these tyre rotation tips into my fleet's maintenance routine?

It is essential to train drivers to regularly check tyres and recognise initial signs of wear. Scheduling regular tyre checks is also highly recommended. If it is necessary to rotate tyres or schedule turning tyres on the rim, our experts recommend consolidating repairs ౼ during a regular service check, regrooving or an oil change for example ౼ in order to reduce downtime.

Preventative tyre maintenance, including tyre rotation, not only saves you time and money, but these practices can boost the safety of your fleet and drivers.

gettyimages 930571046

car going fast on a road by night