header 1

To clear up any misconceptions, let's explore why tyre regrooving tackles most transport companies' economic and environmental challenges, including those of small fleet operators. Michelin's Product Performance Data Manager, Corentin Berger, and Product Category Manager, Pierre Montel, give us further insights.

Regroovable tyres have a limited lifespan.

cta false

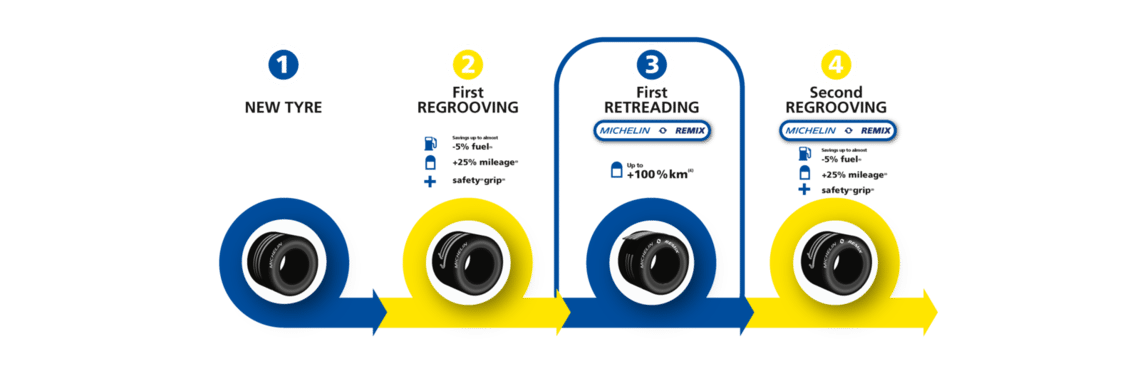

Regrooving can increase the mileage potential of both new MICHELIN tyres and retreaded MICHELIN Remix® tyres by an average of 25%. The process of regrooving is a crucial stage in optimising the mileage of your tyres and using their full potential.

Regrooving truck tyres helps to unlock considerable savings. When performed on a first life MICHELIN tyre (once it reaches 2-4mm of remaining tread depth), and again on a MICHELIN Remix tyre, it delivers a combined 50% increase in mileage performance.

tyre life cycle regrooving michelin tyre

By extending the life of new MICHELIN tyres and retreaded MICHELIN Remix tyres by 25% each, you save one tread with every four regrooves carried out.

Regrooving truck tyres delivers actual cost savings.

cta verytrue

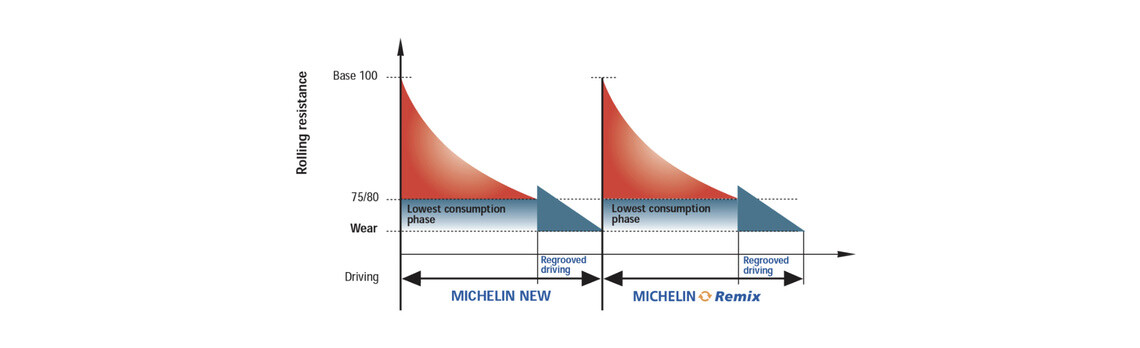

Throughout its life, the tyre’s low rolling resistance allows for reducing fuel consumption and, thus, CO2 emissions. Regrooving is carried out when the tyre has the lowest rolling resistance, enabling you to save up to 5% in fuel consumption(1). Regrooved tyres also offer 25% extra mileage performance in a tyre’s most fuel-efficient state.

Schema about rolling resistance between new and retreaded tyres

How to easily measure the impact on your fleet?

At Michelin, we can help you to calculate data such as raw material savings, fuel savings and, therefore, CO2 savings, to raise awareness of the economic and environmental benefits of regrooving and/or retreading your tyres.

Regrooved truck tyres offer less safety.

cta false

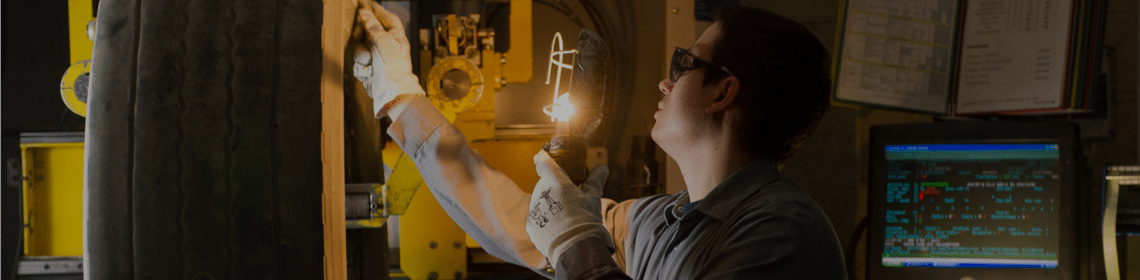

The practice of regrooving consists of cutting new grooves into the existing layers of base rubber which are built into MICHELIN new and Remix tyres as standard, using a specialist regrooving tool. This deepens the tyre’s tread depth so you can regain grip and drive in complete safety. In the wet, a regrooved tyre’s grip and traction improves by around 10% compared to the same tyre when worn (2)

I can regroove any truck tyre.

true but

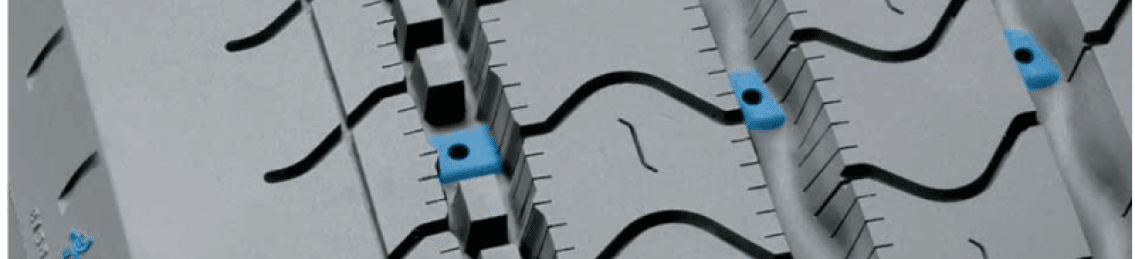

MICHELIN regroovable tyres are marked on the sidewall with the « U » symbol or the words « REGROOVABLE ». Michelin recommends regrooving be carried out when there is still 2-4 mm of remaining tread. All MICHELIN tyres have a regrooving well in the centre of the tread wear indicators, to allow high-quality regrooving to be carried out. It is essential that the regrooving be carried out by a professional in accordance with our recommended guidelines.

Although Michelin advises regrooving bus and truck steer tyres, some countries do not accept the use of regrooved tyres on the front axle.

What a wear indicator looks like ?

download mytechexpert

Regrooving is good for the environment.

cta verytrue

Regrooving tyres extends their life in their most fuel-efficient state. The practice of regrooving means you can reduce CO2 emissions by up to 1.1 kg/100 km per axle(3).

Regrooving also means less waste, as fewer raw materials are used because the tyre's life is extended. It also limits the emission of wear particles, which are more common in new tyres.

Regrooving tyres is difficult to organise

cta false

In order to avoid vehicle downtime during regrooving, we recommend you keep fitted assemblies in stock to optimise the operation. It takes around 2.5 hours to regroove four tyres. And the work can be carried out professionally for you by your local dealer.

Specific regrooving patterns are available for each tyre to guide your regrooving operations. Regrooving tyres provides added grip and traction, optimising the tyre's mileage potential and reducing the fuel consumption.

Ready to test your knowledge on tyre retread tyres?

Don't be fooled by preconceived ideas and read our article to find out more about retreading.

(1) 5.6% reduction in fuel consumption: an internal Michelin study carried out in Ladoux (France) in May 2021, under the supervision of DEKRA, comparing new MICHELIN X® LINETM ENERGYTM Z2 and D2 315/70 R 22.5 tyres with the same regrooved tyres (R 5 mm). Results may vary in real-use conditions and according to weather conditions, road type, tyre size and driving style.

(2) Michelin internal study in 2010 in Ladoux on a polished concrete track. Results may vary in real-use conditions and according to weather conditions, road type, tyre size and driving style.

(3) Michelin study conducted on 1 million tyres provided for Michelin Remix retreading in 2008 and 2009. The difference in the approval rate between retreaded regrooved tyres and retreaded non-regrooved tyres is below 0.2%.

(4) The tread compound and pattern of the MICHELIN Remix tyres are largely the same as those used for new MICHELIN tyres. 90% of the range of MICHELIN Remix tyres uses the same mould and the same materials as new MICHELIN tyres which may lead to up equivalent performance between MICHELIN Remix tyres and new Michelin tyres. Internal evaluations carried out by the Michelin Research and Technology Center based on customer testimonials collected in Europe since 2015.

gettyimages 930571046

car going fast on a road by night