Sustainable mobility: Grow your business, reduce your environmental impact with MICHELIN tyres and solutions

Grow your transport business and reduce your environmental impact with MICHELIN tyres and solutions

The transportation industry is at a crossroads. It’s facing multiple challenges, like driver shortages, inflation, and rising fuel costs, and finds itself at the centre of the climate crisis: Road transport accounts for around 15% of global CO2 emissions. (1)

You might be willing to take action to address the climate crisis, but only if it makes sense for your business. We understand your caution and your challenges.

At Michelin, we are committed to reducing the environmental impact of the transportation industry.

That is why we want to support you and show that thinking sustainably can be beneficial for the reduction of your environmental footprint AND for your business. Step Up is our global approach to do just that.

Let’s STEP UP side by side.

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesTake the steps today

to help improve your business AND reduce your environmental impact!

1- Start by choosing eco-designed tyres

To minimise the environmental impacts of our products and services while maintaining or even improving performance, we follow an eco-design approach.

This involves evaluating impact at every stage of the tyre lifecycle(2) . We can then leverage actions across multiple categories to help reduce the impact of our tyres.

Reducing tyre rolling resistance and weight to reduce fuel consumption

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesFuel/energy represents up to 26% of a fleet’s expenses (3) and has a direct impact on emissions, with one litre of diesel emitting 2.66kg of CO2 (4).

So, using lighter tyres that have lower rolling resistance contributes to the reduction of vehicular emissions AND the reduction of fuel costs.

Increasing longevity to decrease waste

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesBy investing in tyres designed to endure until the last millimetre of the legal wear limit, you decrease the frequency of replacements, keeping your fleet on the road for longer while fighting against waste.

Because greater longevity is just a first step, Michelin wants to provide you with high performance, even with worn tyres. Check out the results of a comparison to competitors above, under DEKRA supervision.

Innovating in renewable and recycled materials

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesWe are continually replacing fossil fuel-based raw materials with recycled and renewable raw materials.(5)

Working with a key partner in sustainability like Michelin helps you satisfy customers who are looking to strengthen their environmental commitment.

Examples of our most energy efficient tyres:

Examples of our most energy efficient tyres:

Make the eco-design choice when you’re buying your new vehicle too! Learn why we’re a reliable partner for Original Equipment manufacturers.

2- Why always buy new? Opt for the multi-life model for truck tyres

Give new life to your truck tyres through retreading and regrooving practices. Implementing a multi-life model is a no-brainer: it can help you reduce costs AND reduce your environmental footprint. Plus, these practices are effective in reducing environmental impact in both the use phase and the raw material phase of your tyres.

Retread tyres

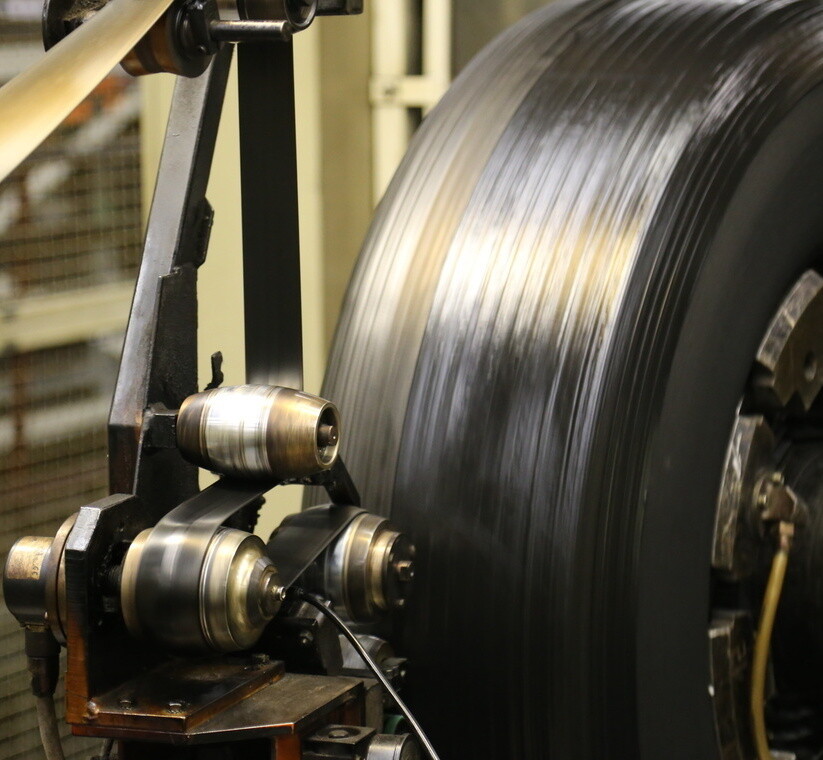

Rechapage d'un pneu en atelier

Retreading

- Costs 40% less than an equivalent new tyre (6)

- Just one retread saves 50 kg of raw material, keeping 115 kg of CO2 from releasing into the atmosphere (7)

Tyre regrooving

Regrooving

- Helps you go further, with up to 25% additional mileage (8)

- Saves up to 5% (9) in fuel consumption, saving up to 251 kg of CO2 (10)

Our sustainability impact calculator quantifies the benefits of retreading or regrooving tyres.

Learn how your actions contribute to a more sustainable future.

Why the multi-life model is a MUST-HAVE

The multi-life model does wonders for your CPK (cost per kilometre). Find out how in the video below.

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookies3- Adopt the right tyre routine maintenance to drive success

While tyres play an important role in reducing your environmental footprint, sustainability encompasses a broader spectrum of practices, from having the right tyre pressure, to rotating your tyres for even wear, to promoting efficient driving behaviours, and more.

Your operating efficiency and environmental impact depends on staying up to date with these practices and technical advice. Our articles offer the latest tips for everyday operations to help you be as efficient as possible, both with your time and resources!

Do you like to stay up to date on industry topics? For more in-depth content on topics like energy efficiency, fuel consumption, and sustainable mobility, check out the MICHELIN For My Business blog

4- Go beyond tyres: Services around tyres and efficient fleet management are key.

Since sustainability is about more than just tyres, it’s essential to have the right connected solutions and/or fleet management to strengthen your environmental commitment. Don’t worry about managing your tyres or optimising your fleet operations. Michelin’s network of experts has got you covered. Two of our flagship service offerings:

Discover MICHELIN Connected Fleet

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesBy optimising driver and vehicle behaviours, our fleet management solutions optimise fleet efficiency, safety and tyre performance, which in turn helps you lower fuel consumption and CO2 emissions.

Discover MICHELIN Effitires

To watch this video, you'll have to accept some cookies from Youtube platform. Just click on the button below to open the cookie module.

Accept youtube cookiesThis service is designed to increase uptime, reduce costs, AND lower your CO2 emissions through outsourcing the management of your tyres. How? It all goes back to optimising the life of your tyre up until the legal wear limit.

Learn more about our own ambitions for a sustainable future.

(1) Source: https://ourworldindata.org/co2-emissions-from-transport

(2) From the extraction of raw materials, to manufacturing, logistics, use and collection and recycling

(3) Source: Michelin Total Cost of Ownership Split study conducted by Ducker Carlisle in 2024, based on average of costs reported by fleet customers during phone interviews.

(4) Source: UK Government GHG Conversion Factors for Company Reporting, 2024

(5) Renewable materials obtained from natural resources that can be reconstituted over a short period of time on a human scale, and recycled materials obtained by any recovery operation whereby industrial or post consumer waste is reprocessed into products, materials or substances

(6) Michelin Internal study performed in 2022 by Competitiveness analysis tool performed on Europe perimeter comparing MICHELIN brand new tyre vs. MICHELIN Remix®.

(7) The CO2 saving associated with the retreading operation is calculated from the associated material saving. In terms of material saving, a MICHELIN Remix® retreaded tyre covers up to 100% of the mileage of a new MICHELIN tyre (the tread mix and tread pattern of MICHELIN Remix® tyres are largely the same as those for new MICHELIN tyres; 90% of tyres in the MICHELIN Remix® range are made from the same mould and the same materials as new MICHELIN tyres and therefore perform equally as well; according to internal tests conducted by the Michelin Research and Technology centre and customer testimonials collected in Europe since 2015). A new tyre weighs 70 kg on average. A tyre ready to be retreaded weighs 50 kg on average. The CO2 impact of a retreaded tyre is linked to the material saving, or 115 kg of CO2 representing 50 kg of raw material savings, at a rate of 2.3 kg of CO2* per kg of raw materials.

* Equivalence between CO2 and a litre of fuel or kilogram of raw material is calculated in this way: the emissions factor of 3.24 kg of CO2 for 1 litre of diesel comes from the life cycle assessment conducted by ADEME for pure diesel. It includes emissions during the diesel production stages (17%) and during its combustion (83%). Source: ADEME, Study «Well to wheel - JEC», v4, july 2014. The emissions factor of 2.3 kg of CO2 for 1 kg of tyre comes from the life cycle assessment calculations for production of a tyre cradle to gate), conducted internally by Michelin using the calculation rules developed by the tyre manufacturing profession (TIP). It includes stages including extraction of raw materials, transportation, manufacturing, and distribution. Source: UL Environment Standard, «Product Category Rules for preparing an Environmental Product Declaration for the product category: Tyres», v3.05, february 2022.

(8) Compared to a worn non-regrooved MICHELIN tyre. Based on a 4-mm average regrooving. Information taken from recommendations made by the French tyre manufacturers’ federation TNPF in 2013 according to which regrooving of worn tyres increases tyre lifetime by using all available rubber.

(9) Internal study carried out at the Michelin test tracks in Ladoux (France) on 5 May 2021, under DEKRA supervision (report No. 21CPAEXT-030). For the comparison between new tyres and regrooved tyres (R5 mm), two identical Volvo FH500 trucks were used, fitted with 315/70 R 22.5 MICHELIN X® LINE ENERGY™ Z2 & D2 tyres and each towing a fully loaded (40 tonnes) Schmitz Cargobull trailer fitted with 385/55 R 22.5 MICHELIN X® LINE ENERGY™ T tyres at identical pressures (8.5 b, 7.5 b and 9.0 b). Results may vary depending on weather conditions, road type, tyre size and driving style.

(10) The CO2 savings from the Michelin multi-life model, are accentuated thanks to the fuel savings linked to regrooving (up to 5.4%(1)). According to a study under real conditions of use (using 315/70 R 22.5 tyres fitted to the drive and steering axles of a 4x2 truck used for international and national long distance, that have exceeded 50% wear), the average mileage for MICHELIN X® LINE ENERGY™ Z2 and MICHELIN X® LINE ENERGY™ D2 tyres is 232,200 km before regrooving* (*Michelin internal source and calculation, based on measurements taken by the Michelin teams during customer inspections on 488 axles, in Austria, Belgium, Croatia, the Czech Republic, France, Germany, Greece, Hungary, Italy, the Netherlands, Poland, Portugal, Romania, Serbia, Slovenia, Spain, and Turkey, over the period from 2020 to 2023), with a simulation based on the results collected suggesting extrapolation of the lifespan until 3 mm remains. The results may vary depending on the weather and road conditions. The view is that our tyres travel up to 25% (2) further thanks to regrooving, i.e. 58,050 km (232,200 x 25%). The fuel savings are calculated over the distance travelled by the regrooved tyres (58,050 km) at an average consumption of 29.5 L/100 km for new tyres and 27.91 L/100 km for regrooved tyres (source: DEKRA report No. 21CPAEXT-030). 29.5 x 5.4%, i.e., a saving of 1.59 L/100 km for an articulated truck and tri-axle trailer (thus 12 tyres). Consequently, there is a saving of 0.13 L/100 km per tyre (1.59 L/12), i.e., 0.13 L x 58,050 km/100 = 77 litres of fuel saved when driving on regrooved tyres, thus a saving of 77 litres of diesel x 3.24 kg of CO2 = 251 kg of CO2. The emissions factor of 3.24 kg of CO2 for 1 litre of diesel comes from the life cycle assessment conducted by ADEME for pure diesel. It includes emissions during the diesel production stages (17%) and during its combustion (83%). Source: ADEME. Base Empreinte, Étude Carbone, Version 22.0.0, 02/08/2022. Thus 77 x 3.24 kg of CO2 = 251 kg of CO2.