header end of life tyre

Circularity is the next technological revolution and Michelin is leading the charge in transforming the tyre sector by turning end of life tyres into a valuable resource. So what exactly is an end of life tyre? Put simply, they are truck tyres that can no longer be used, retreaded or regrooved. We chatted with Fabien Gaboriaud, Senior Vice President of Solutions for Materials Circularity at Michelin to explore the challenges and opportunities surrounding end of life tyre management. Discover how the tyres you choose for your fleet can improve circularity and minimise environmental impact.

fabien gaboriaud senior vice president of solutions for materials circularity at michelin

Fabien Gaboriaud, Senior Vice President of Solutions for Materials Circularity at Michelin

What is Michelin's approach to minimising the environmental impact of end of life tyres?

Fabien Gaboriaud: Michelin's commitment to the planet starts with a fundamental principle: if you want to minimise your impact on the environment, you must start by measuring it. This belief has driven us to evaluate the environmental impact of our products for over three decades.

One of the first areas we focused on was rolling resistance. We led the way in showing how it affects fuel consumption, even when it was a niche concept. We created a narrative around its importance by highlighting the consequences it has on the planet and a fleet’s budget as well!

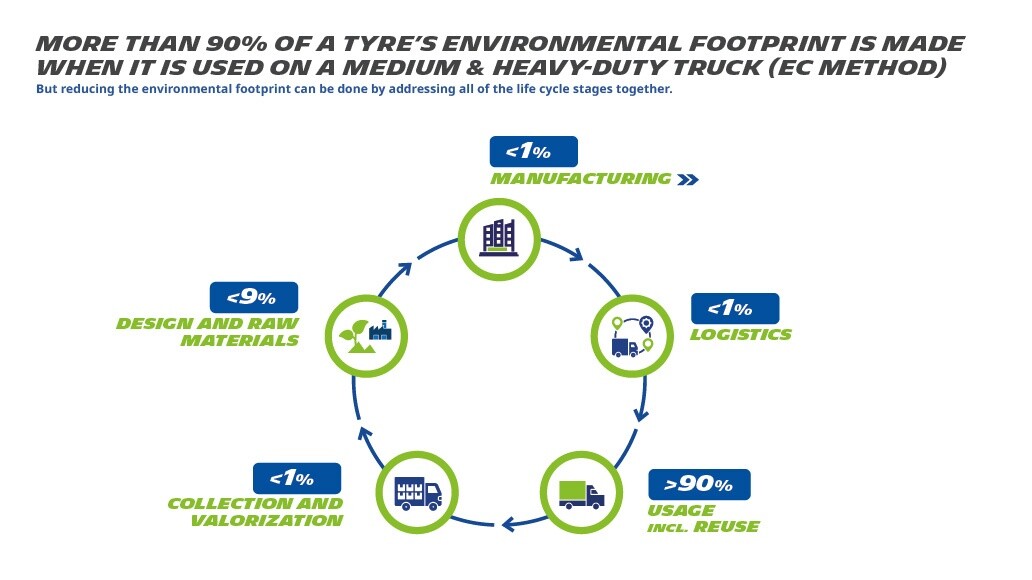

We were also pioneering with our approach to life cycle analysis, being amongst the first to adopt such a comprehensive approach. This method meticulously examines a tyre’s environmental impact ౼ from sourcing and processing raw materials, such as rubber, steel, carbon black, and textile fibers, to end of life tyre collection and truck tyre recycling ౼ in order to focus on the most critical impacts. As a result, life cycle analysis is now standard practice at Michelin. Every designer integrates climate performance and environmental considerations into their product designs, ensuring quantification of environmental impacts and sustainability throughout the entire life cycle.

tyre s environmental footprint

What are the environmental impacts of Michelin’s programmes for recycled tyres?

Fabien Gaboriaud: Michelin isn't just a major brand; we're a company committed to long-term environmental responsibility. For example, our tyre recycling programme aims to use 100% renewable and recycled materials in our tyres by 2050. This is an excellent goal that I’m very proud of, but we cannot forget that sustainability goes beyond simply using renewable resources. We make it a point to conduct a rigorous life cycle analysis on every material choice for example rubber, steel, carbon black, and textile fibers. That means, we only integrate materials that demonstrably benefit the planet throughout their entire lifecycle. This ensures our commitment to sustainability translates into real environmental progress.

How can we solve the problem of end of life tyres recycling?

Fabien Gaboriaud: The first step is to stop thinking of end of life tyres as waste, and instead as a fantastic carbon resource. I think everyone can agree that landfills with mountains of end of life tyres, and overall tyre incineration are not great for the planet. Transforming truck tyres into fuel could be a promising solution. But what if we could integrate recycled materials back into new tyres? This closed-loop system represents a true path to minimising environmental impact. By creating a circular economy for old tyres, we can significantly reduce our environmental footprint.

Sounds exciting! Where does this technology stand today?

Fabien Gaboriaud: In March 2023, Michelin supported the creation of a joint venture by Enviro, a tech start-up, and Antin Infrastructure Partners, an investment fund, to accelerate the recycling of end of life tyres on an industrial scale in Europe. Enviro’s technology extracts two very useful products from end of life tyres: pyrolysis oil and recovered carbon black (RCB).

Pyrolysis oil is basically fuel that can be used to help cut down on emissions and decarbonise certain industries. This is a wonderful first step, however the problem with fuel is that you can only use it once. Recovered carbon black (RCB) on the other hand can be used to manufacture new products ౼ in other words, transforming end of life tyres into raw materials that can be integrated into a new tyre. This closed-loop system is a game-changer. It slashes carbon emissions by over 80% compared to the use of virgin carbon black1. It's a win for Michelin, and a win for other industries that can use these recuperated materials.

The problem with fuel is that you can only use it once. Recovered carbon black (RCB) on the other hand can be used to manufacture new products.

The first factory to come out of this Antin and Enviro joint venture is being built in Sweden, and it'll be up and running by 2025. They're starting with recycling 35,000 tonnes of end of life tyres a year, but the plan is to expand across Europe and eventually hit one million tonnes annually.

Have there been significant wins in terms of dealing with scrap tyres?

Fabien Gaboriaud: Years ago, our industry began collaborating and organising to come up with a plan to solve a big problem: the valorisation of end of life tyres. On top of the negative environmental impact, truck tyres left abandoned in landfills were a major image problem as well. To tackle this head-on, a collaborative effort led to an impressive 88% tyre collection rate2 – a significant achievement, especially compared to other sectors. In short, the high tyre collection rate for end of life tyres puts the industry in a prime position to move towards a circular economy.

Sounds like a great start! What challenges do you anticipate?

Fabien Gaboriaud: The first challenge is not a technical challenge, it’s a mindset one. As an industry, as a global society, we need to move away from transactional negotiations and towards negotiating interactions. By that I mean, orchestrating interactions with all stakeholders to help structure new value chains and new technology ౼ at times with our suppliers, at other times with our customers and even players whom we consider to be competitors. That’s the beauty of the circular economy ౼ it creates coalitions where everyone is a stakeholder.

We're working towards using 100% renewable and recycled materials in our tyres by 2050. That’s the beauty of circularity ౼ it creates coalitions where everyone is a stakeholder.

Another crucial mindset shift involves putting an end to the idea that renewable and recycled materials need to be cheaper. It’s just simply not the case. So, what we need are leaders who will pay more, consumers who will pay more. We need to stop thinking of it as paying more for a product and instead think of it as paying more to preserve our planet. Because tomorrow, the environmental impact, the CO2 impact, the biodiversity impact, will have an even higher cost. Across our industry, we’re starting to see this mindset shift being integrated into strategic decisions.

Is there a local aspect to dealing with end of life tyres?

Fabien Gaboriaud: Absolutely. We recognise that the circular economy requires a much more local approach ౼ notably because regulations and practices when it comes to collection, processing and the integration of recuperated materials vary considerably from region to region. So, this is really a dimension where we know that logistics will play a key role in ensuring that we decarbonize the entire industry.

How can fleet owners be sure that an “eco tyre” is truly environmentally friendly?

Fabien Gaboriaud: Customers need to be very careful when choosing truck tyres based on environmental criteria, as their performance may not be comparable, which in turn serves to undermine the environmental benefit. Even with 100% truck tyre recycling content, a truck tyre that wears out quickly needs frequent replacements, which negates the initial resource savings.

How is Michelin innovating in this area?

Fabien Gaboriaud: Michelin thrives on tackling challenging issues. We believe the tougher the problem, the greater the opportunity to innovate for our customers and society as a whole. This translates to a double benefit: environmental progress without compromising tyre performance.

tyre s life cycle

How can Michelin assist with truck tyre management and tyre collection?

We are committed to responsible tyre collection, sorting and processing. That's why we're developing an innovative RFID project. This technology assigns each tyre a unique ID, allowing fleets to track their journey throughout the entire life cycle.

This data is invaluable. Fleets can analyse service activities and ensure that truck tyres comply with regulations and their own sustainability values at every stage. By following each tyre’s journey, they promote responsible end of life tyre management and a more sustainable future.

Looking towards the future, what advice would you give to fleet owners?

Fabien Gaboriaud: We understand the landscape of environmental promises is crowded. Michelin, however, has a proven track record of delivering on sustainability goals. We're developing circularity solutions that build on the circular economy and our existing climate initiatives. To support this ecosystem of responsible choices, we encourage everyone, including all tyre manufacturers, to open communication. To our customers facing challenges or seeking guidance, I say: we're here to collaborate!

Remember, sustainability requires commitment and investment. It's not a quick path to savings, but a demonstration of social responsibility and a way to shape the future.

Remember, sustainable truck tyre management requires commitment and investment. It's not a quick path to savings, but a demonstration of social responsibility and a way to shape the future. In ten years, I believe companies that haven't embraced this path will struggle. We're actively structuring projects, preparing for tomorrow and seeking partners to push these boundaries together.

FAQs

Tyre life expectancy varies depending on the use case. Factors such as driving terrain, maintenance, truck weight and driving style can wear down tyres faster. Tyre selection plays a key role in its lifespan, as the composition of materials — including the rubber compound and steel reinforcements — varies according to the tyre’s intended use.

End of life tyres—those that can no longer be used, retreaded or regrooved—are typically collected and processed through recycling, energy recovery, or repurposing schemes, depending on local regulations and infrastructure.

Choosing the right tyre for the right job is key. It is also essential to regularly check tyre pressures, wear and damage, plus keep up with proper tyre rotation and turning tyres on the rim.

Michelin incorporates a range of technologies into its truck tyres, including INFINICOIL, POWERCOIL and DURACOIL, which serve to boost a tyre’s overall robustness.

1. Michelin, Recyclage, Dossier de fond. Pg. 14. Feb. 2024.

2. Michelin, Recyclage, Dossier de fond, Pg. 10. Feb. 2024. Deloitte – TIP 2019 – 45 countries.

gettyimages 930571046

car going fast on a road by night