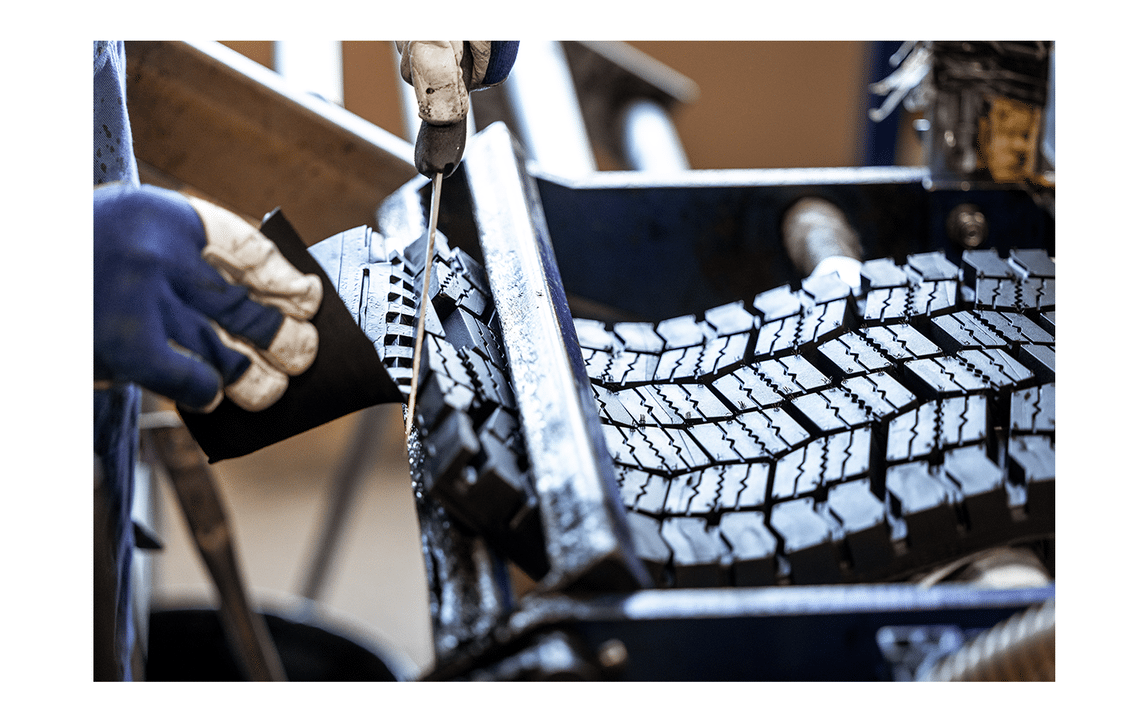

00 technician repairing a heavy goods vehicle tire before truck tyre retreading

In 1923, the world was on the move. Freight trains chugged through cities, trucks began conquering longer distances, and roads grew more essential by the day. But those roads were far from uniform ౼ often poor in quality, varying greatly from one region to the next. On top of that, repairs were nowhere near today’s standards. The result: tyres wore down fast, and replacing them was expensive for transport companies. That’s when Michelin made a quiet, revolutionary move: it introduced truck tyre retreading.

01 truck tyre retreading technician working in a workshop

This was more than just a technical innovation. It asked a radical question for its time: what if a truck tyre could live more than once?

The early days of truck tyre retreading:

Innovation born of necessity

Post-World War I Europe was rebuilding, and efficiency meant everything. Fleets needed tyres tough enough for rough roads but affordable enough to keep operations running. The Michelin brothers, Édouard and André, were already focused on improving durability, resulting in reduced tyre cost-per-kilometre for their customers.

Through their testing, they noticed a pattern: while the tread ౼ the outer rubber that grips the road ౼ wore down fairly quickly, the inner structure of the tyre, or casing, remained in good condition. That sparked an idea. What if, instead of replacing the entire tyre, you could just replace the tread?

This simple yet powerful concept led to the birth of truck tyre retreading ౼ a process that reuses the casing and applies a fresh tread to extend the tyre’s life. For more than 100 years, Michelin has been at the forefront of this practice, driving innovation and setting industry standards that continue to shape the future of transport.

Steel and strength: The backbone of a second life

As the years rolled on, the demand on trucks ౼ and their tyres ౼ only grew. By the mid-1930s, trucks were carrying heavier loads, and existing tyre casings weren’t always up to the task. That’s when Michelin introduced another major innovation.

In 1937, they unveiled the “Metalic” ౼ the first truck tyre with a steel casing. Unlike earlier versions made with multiple fabric layers, this new casing used just four plies of steel cord, offering superior strength and durability. What’s more, it wasn’t just built to last ౼ it was built to be retreaded.

This breakthrough turned truck tyre retreading from a helpful idea into a long-term strategy. Tyres were now being designed from the start to live multiple lives, making it easier for fleets to make their investments last as long as possible.

The dawn of industrialisation

The next big leap came in 1946. In the town of Avallon, in Northeast France, the first hot-retread truck tyre rolled off the production line. And the timing could not have been better! In the post-war years, when resources were scarce and transport operators needed every saving they could find, retreading proved to be a lifeline.

At the time, the facility was owned by Pneu Laurent, a pioneer in the field. It would only be in 1973 that Michelin became the majority shareholder, bringing this expertise fully into the company’s portfolio and proving its commitment to building trust in the process across the industry.

Did you know there are two ways to retread?

Truck tyre retreading illustrated with a new MICHELIN Remix® tyre

Hot retreading, a true game-changer, fuses a fresh tread and sidewalls onto a carefully prepared casing by curing the whole assembly in a mould under heat and pressure. The result is nearly indistinguishable from a new tyre – both in look and performance.

Pre-molded tread used for cold truck tyre retreading

Cold retreading applies a pre-moulded tread to the casing and cures it in an autoclave ౼ providing a flexible, cost-efficient alternative.

With these methods, fleets are able to keep trusted casings rolling longer, safely and reliably.

Retreading the future: A technological turning point

By 1966, truck tyre retreading had earned its place in the transport industry. But Michelin wasn’t satisfied with the status quo. That year, the company introduced the Remix process ౼ a method that used the same materials and manufacturing specifications as a new tyre. In essence, it gave retreaded tyres a “factory-fresh” second life.

The implications were huge. MICHELIN Remix® tyres could now match up to 100% of the mileage of a new tyre1. For fleets, this wasn’t just a sustainable option, it was a smart investment. The tyre retreading cost dropped significantly over time, as casings could now be used multiple times without sacrificing reliability or safety.

Retreading at scale

Decades passed, and truck tyre retreading kept gaining ground. As fleets became more sophisticated, so did Michelin’s processes. In 2021, the company hit a symbolic milestone: the production of its 18 millionth MICHELIN Remix® tyre, manufactured in Homburg, Germany, Michelin’s largest retreading facility in Europe.

That figure made a statement! It reflects the growing trust fleets have placed in retread solutions. It also highlights how far truck tyre retreading has come ౼ from a niche option to a core part of truck fleet management.

Retreading today: A response to global challenges

A hundred years after its first retread, Michelin’s original idea feels more relevant than ever. Today, fleets face a new set of challenges: rising fuel prices, supply chain instability, inflation, and growing pressure to reduce carbon emissions. Truck tyre retreading offers a solution that tackles all of these at once.

Each retread saves around 50 kilograms of raw materials2 – rubber, steel, and oil-based components – compared to producing a new tyre. Multiply that by thousands of tyres, and the environmental benefit is enormous. And Michelin goes even further: end-of-life tyres can now be transformed into raw materials for new tyres. This process extracts pyrolysis oil, used as fuel to cut emissions, and recovered carbon black, which slashes carbon emissions by over 80% compared to virgin carbon black. The result: a truly closed-loop system.

Even more impressively, for every 100 tyres retreaded, Michelin estimates that over 11.6 tonnes of CO₂ emissions from associated material services are avoided3. That’s a powerful win for the planet and for fleet sustainability goals.

There’s also less waste. Fewer discarded tyres means fewer end-of-life disposal challenges and a more circular economy. In today’s climate-conscious world, truck tyre retreading isn’t just a cost-cutting tool, it’s a long-term sustainability strategy.

The retreading journey continues

What began as an idea to help truck drivers go a little further on the same tyre has become a global success story. A hundred years later, truck tyre retreading is a proven, scalable, and increasingly vital solution in an industry that never stops moving.

For over 10 years, Michelin has offered the possibility of a second premium hot retread MICHELIN Remix® for tyres used on construction sites. Since 2024, this option has been expanded to the most common use case: goods transport, with the dedicated MICHELIN X® Multi range.

To keep truck tyre retreading techniques state-of-the-art, Michelin continues to develop advanced digital solutions. For example, every Michelin truck tyre is equipped with an RFID chip to track the casing through its life and retrieve essential information for retreading. Algorithms powered by artificial intelligence now scan the casing and verify its integrity before it is retreaded, ensuring the highest level of quality and safety.

Retreading is not only about performance and cost savings and reducing carbon footprint; it is also about people. Across Europe, the industry sustains some 32,000 local jobs4, with each retreaded tyre generating four times more employment than an imported, non-retreadable tyre.

And the journey of a tyre does not end with retreading. Retreaded tyres can also be regrooved, further reducing costs and enhancing durability, allowing fleets to keep their casings rolling even further.

As Michelin looks to the future, it remains committed to evolving its retread technology ౼ driving progress for transport operators, protecting the planet, and ensuring that tyres, like the trucks they support, can go the distance.

FAQ:

Absolutely. Truck tyre retreading is a well-established practice that gives tyres a second, third or even fourth life. As long as the original tyre casing was designed for multiple uses and is in good condition, it can be retreaded several times safely and reliably.

Starting a truck tyre retreading business requires significant investment in specialised retreading machinery as well as a manufacturing facility. You’ll need to secure the right equipment, source quality casings, and adhere to strict safety and quality standards. Partnering with established manufacturers like Michelin can provide valuable training, technical support, and quality assurance to help optimize your operating costs and service quality.

Yes! Retreaded tyres are completely legal in the UK as long as they meet UK safety standards.

The number of times you can retread a tyre depends on the quality and condition of the original casing. For example Michelin’s REMIX 2 introduces the opportunity of a second premium retread ౼ demonstrating the exceptional endurance the casings.

On average, a retreaded tyre costs about 60% of the price of a new tyre — for roughly the same mileage — delivering major savings for fleets.

1. The tread compound and pattern of the MICHELIN Remix® tyres are largely the same as those used for new MICHELIN tyres. 90% of the range of MICHELIN Remix® tyres uses the same mould and the same materials as new MICHELIN tyres which may lead to up to equivalent performance between MICHELIN Remix® tyres and new Michelin tyres. Internal evaluations carried out by the Michelin Research and Technology Center based on customer testimonials collected in Europe since 2015.

2. https://business.michelin.co.uk/blog/articles/100-years-of-truck-tyres-retreading

Le rechapage MICHELIN Remix® ne nécessite que 20 kg de matières premières supplémentaires en moyenne, ce qui équivaut à une économie de 50 kg de matières premières par rapport à la production d’un pneu neuf MICHELIN. Comparaison interne réalisée au centre de recherche et développement de Michelin – en comparant le poids moyen de pneus Michelin Remix® avec celui de pneus neufs Michelin en plusieurs dimensions.

3. The CO2 saving associated with the retreading operation is calculated from the associated material saving. In terms of material saving, a MICHELIN Remix® retreaded tyre covers up to 100% of the mileage of a new MICHELIN tyre (the tread mix and tread pattern of MICHELIN Remix® tyres are largely the same as those for new Michelin tyres; 90% of tyres in the MICHELIN Remix® range are made from the same mould and the same materials as new Michelin tyres and therefore perform equally as well; according to internal tests conducted by the Michelin Research and Technology centre and customer testimonials collected in Europe since 2015). A new tyre weighs 70 kg on average. A new tyre ready to be retreaded weighs 50 kg on average. The CO2 impact of a retreaded tyre is linked to the material saving, or 115 kg of CO2 representing 50 kg of raw material savings, at a rate of 2.3 kg of CO2* per kg of raw materials.

* Equivalence between CO2 and a litre of fuel or kilogram of raw material is calculated in this way: The emissions factor of 3.24 kg of CO2 for 1 litre of diesel comes from the life cycle assessment conducted by ADEME for pure diesel. It includes emissions during the diesel production stages (17%) and during its combustion (83%). Source: ADEME, Study «Well to wheel - JEC», v4, july 2014. The emissions factor of 2.3 kg of CO2 for 1 kg of tyre comes from the life cycle assessment calculations for production of a tyre cradle to gate), conducted internally by Michelin using the calculation rules developed by the tyre manufacturing profession (TIP). It includes stages including extraction of raw materials, transportation, manufacturing, and distribution. Source: UL Environment Standard, «Product Category Rules for preparing an Environmental Product Declaration for the product category: Tires», v3.05, february 2022.

4. https://www.circulary.eu/project/tripling-tyres-michelin/?utm

5. https://www.michelin.com/en/publications/products-and-services/truck-tire-retreading-remix

gettyimages 930571046

car going fast on a road by night