00 truck tyre innovation demonstrated by michelin mobile repair trucks

Road transport never stops evolving. For generations, carriers, drivers, and fleet operators have faced new challenges ౼ whether it’s carrying heavier loads, boosting fuel efficiency, or meeting tougher environmental standards. And every step of the way, Michelin has been right there, staying one move ahead with solutions that truly make a difference. This commitment is evident in every new tyre technology Michelin develops.

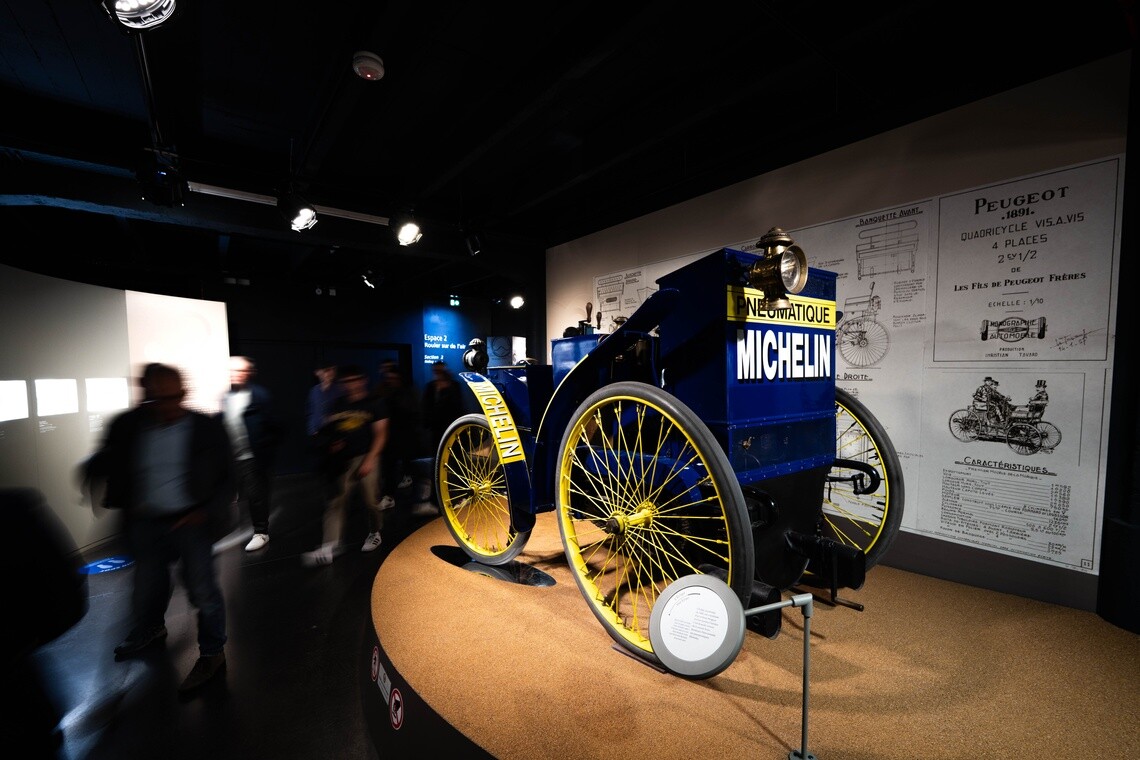

01 an antique replica of the 1895 michelin l éclair car the first on pneumatic tires

PrC)sentation des nouvelles gammes de pneus Michelin Poids Lourd C Ladoux, Clermont-Ferrand. Photo : JC)rC4me Cambier/MICHELIN

For Michelin, truck tyre innovation has always been about solving real challenges on the road. From early designs that reduced downtime to today’s breakthroughs that aim to make punctures a thing of the past, Michelin’s story is one of smart ideas built for real-world use.

Let’s take a closer look at how Michelin tyre innovation has shaped the industry for more than a century ౼ and why it continues to make life easier for drivers and fleets today.

A true partner since the start

When André and Edouard Michelin founded the company back in 1889, they weren’t just looking to make tyres ౼ they wanted to develop technologies to make transport simpler, safer, and more efficient.

One of the earliest new innovations in tyres came in 1908, when the Michelin brothers introduced the twin drive axle tyre. At the time, pneumatic tyres were beginning to prove their worth – offering unrivalled comfort for passengers, reduced noise, and the ability to carry heavier loads. And yet, they still faced the problem of overheating and bursting. Michelin solved this by pairing two tyres instead of one, which heated up less quickly and proved far more resistant. This early truck tyre innovation gave fleets the confidence to carry more with less hassle, setting a new standard for heavy-duty performance.

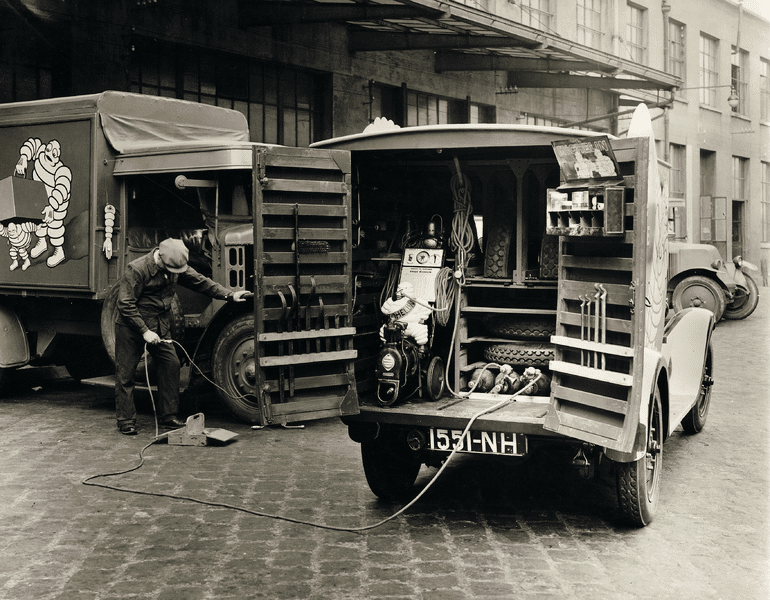

By 1928, Michelin was already thinking beyond tyres. The MICHELIN inflator ౼ durable, precise, and easy to use ౼ helped fleets make their tyres last longer and avoid costly breakdowns. It proved that sometimes the smartest innovations aren’t the flashiest, but the ones that quietly make work easier every day.

Around the same time, Michelin also began sending out travelling advisors to meet fleet operators face to face. These experts shared simple, practical tips to extend tyre life and reduce maintenance costs ౼ showing customers that the company wasn’t just focused on selling tyres, but on building long-term trust as well. Over the years, what started as “Care and Services” visits evolved to include preventive visits to check equipment and installations. By the 1990s the Group launched MICHELIN Fleet Solutions to help fleets optimise the life of tyres by managing and maintaining them.

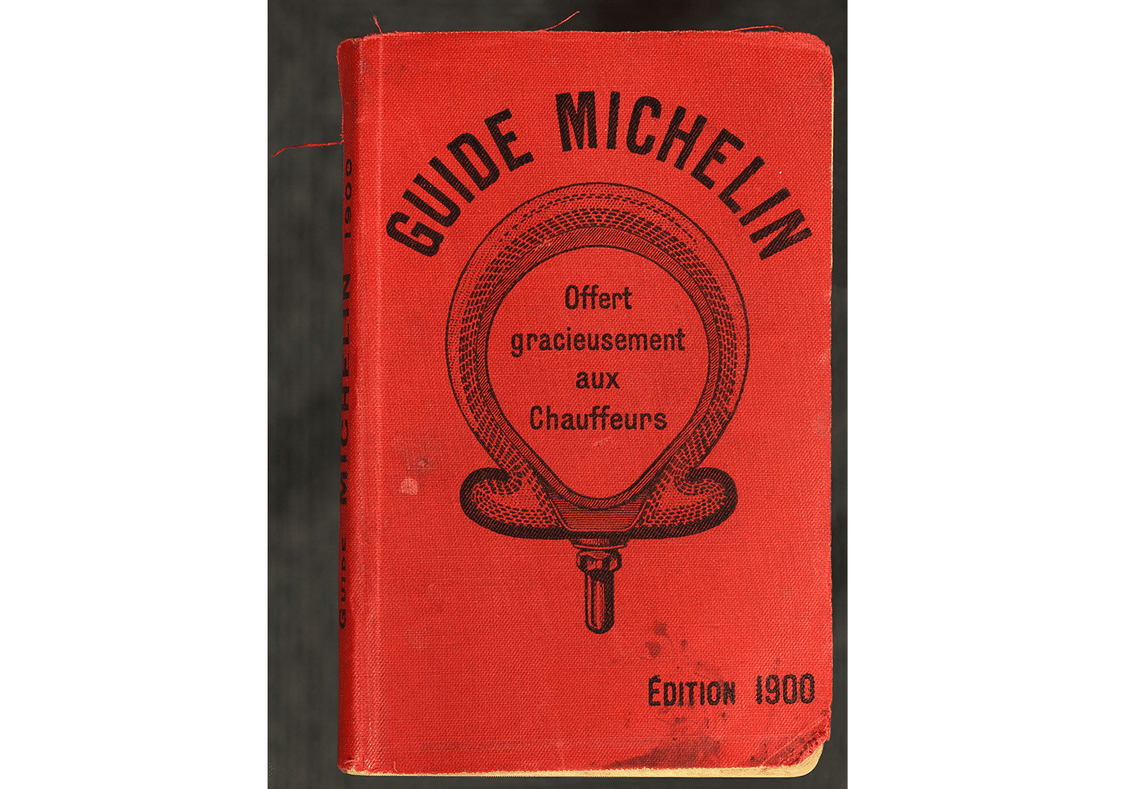

the michelin guide reflects how innovation in tyres enhances the full driving journey

Beyond technology, Michelin was also building an ecosystem of support – road maps, guidebooks, and practical tools to help drivers plan their journeys and care for their vehicles. Case in point: The MICHELIN Guide, created in 1900 and showcased at the World’s Fair. What began as a practical guide for motorists with maintenance tips and useful addresses, expanded to include hotel listings, scenic routes and restaurant recommendations, eventually evolving into today’s prestigious star rating system for the world’s best dining. This showed that Michelin’s spirit of innovation extended to the entire driving experience. These early decades shaped Michelin’s reputation not just as a tyre maker, but as one of the world’s first true tyre innovation companies, and a trusted partner to drivers and fleets alike.

New innovation in tyres takes on comfort and savings

In the 1930s, transport demand was booming. Michelin responded with a series of clever designs to improve comfort, durability, and operating costs ౼ including the Triomphe Confort tyre, with lower inflation pressure and therefore a smoother ride. Plus, it introduced the stronger and more resilient Michelin U tyre, developed to withstand poor-quality roads.

As Michelin searched for ways to make tyres more resistant to wear and damage, engineers turned their attention to the tyre’s architecture. Convinced that stronger materials could provide the answer, they spent six years studying the interaction between metal and rubber. The result was the addition of flexible yet resilient drawn steel wire, which led to the launch of the first steel-cased tyre in 1937: the Metalic. Reinforced with steel, it could handle heavy loads and tough terrain. A milestone in truck tyre innovation, it showed that Michelin was listening carefully to what heavy-duty transport firms really needed.

the metalic was the first steel cased tyre a milestone in truck tyre innovation

The radial revolution: A defining moment in Michelin tyre innovation

enhancing truck performance through michelin x michelin first radial truck tyre innovation

After the Second World War, Michelin introduced one of the greatest milestones in tyre history: the radial. This innovation addressed two major concerns: strengthening the casing to make it more resistant to load and speed, and making the tread less sensitive to road abrasion. The first radial heavy duty tyres were marketed in 1952 under the name ‘MICHELIN X’. They covered twice as many kilometres as other tyres and offered significant fuel savings while providing excellent road holding on all types of terrain. This single truck tyre innovation, a landmark in new tyre technology, transformed fleet economics, allowing operators to drive further on less fuel and with fewer replacements.

Did you know?

In the 1950s, the rise of articulated lorries pushed Michelin to refine its tyre ranges. By the 1970s, tyres were classified not just by driving type but also by axle position, marked with letters: Z for steering and drive, D for drive axles, and T for trailers.

By the 1950s, Michelin advanced further with the introduction of steel-cord tyres. Designed for multiple retreads, they boosted service life and lowered overall tyre retreading costs.

This period cemented Michelin’s reputation as a manufacturer that didn’t just meet the demands of the present but anticipated the needs of the future. For hauliers, Michelin’s tyre innovations translated into real savings, fewer breakdowns, and the ability to move goods faster and further than ever before.

Load-bearing power and long-term thinking

By the late 1960s, fleets were carrying heavier and heavier loads. Michelin stepped up with the Pilot 80 series—the first low-profile truck tyre. Wider, lighter, and able to work with stronger brakes, it gave operators the confidence to move bigger payloads safely. Another leap forward in truck tyre innovation.

The arrival of the MICHELIN Remix® process in the 1970s was made possible by Michelin’s earlier RenoviX innovation, which replaced not only the tread but also several layers of steel cord. The MICHELIN Remix® process refined this idea: instead of throwing away a worn tyre, operators could replace three out of four steel cable layers. This truck tyre innovation extended service life, cut retreading costs, and reduced waste ౼ decades ahead of today’s laser focus on sustainability.

how the michelin remix process reshaped truck tyre innovation

Did you know.

In the early 1960s, Michelin worked closely with Pneu Laurent to expand its tyre retreading business. Their partnership was formalised in 1973, when Pneu Laurent became a Michelin subsidiary.

By the end of the 1970s, Michelin launched the Double X tubeless tyre. Easier to mount and dismount, it cut workshop time and kept fleets moving. For busy operators, every hour saved made a difference.

In 1995, Michelin began its mission to improve rolling resistance with the launch of the first low rolling resistance tyre for heavy goods vehicles, the MICHELIN EnergyTM XZA, with a rolling resistance coefficient of 6 kg/T. This mission has continued over the decades, most notably in 2017 with the MICHELIN X® Line EnergyTM Z2 – the first tyre in the range to achieve a rolling resistance coefficient below 4 kg/T.

Step back and you’ll see a pattern: every big leap forward addressed both the fleet manager’s bottom line and the driver’s daily reality. Better safety, less downtime, and more miles per tyre all added up to stronger, more resilient transport networks with lower CO2 emissions.

Current Michelin tyre innovations and digital solutions shaping the future

Fast-forward to today, and Michelin is still leading the way with game-changing new tyre technology, pushing the boundaries of sustainability, digitalisation, and new design concepts – all the while providing practical solutions for current use cases. For example, all of Michelin’s HGV tyres are designed to be ready for both traditional internal combustion engines and heavier electric vehicles (EVs), which demand more torque.

Here’s a look at some key areas of development:

1. Airless tyres and digital solutions

In recent years, Michelin has made several breakthroughs in AIRLESS technology ౼ with the aim of eliminating the risk of punctures altogether by replacing compressed air with a load-bearing structure. For fleets, it means greater peace of mind on the road, optimised productivity, reduced maintenance needs and fewer replacements ౼ a truly new innovation in tyres.

Michelin airless tyre prototype showcasing innovative puncture free design for safer more sustainable truck

2. Connected tyres for smarter fleets

Onboard sensors are another major step forward. With real-time data on inflation pressure, temperature and from tyre tread sensors delivered through MICHELIN Connected Fleet, operators can spot issues before they become problems. This marks a new phase of truck tyre innovation, where digital intelligence improves safety and efficiency.

3. Sustainability at the core

Michelin is also leading with our pledge for 100% sustainable tyres by 2050. Recent launches include a car tyre with 45% sustainable materials and a bus tyre with 58%. Natural rubber, recycled carbon black, sunflower oil, rice husk silica, and recycled steel are just the beginning. These tyres prove that tyre recycling innovation goes hand in hand with high performance ౼ and is once again, another reason Michelin stands out among tyre innovation companies worldwide.

And the journey is far from over. Michelin is investing in research around hydrogen-powered trucks, electric vehicle compatibility, and even smarter data-driven tyre ecosystems. The goal is clear: to give fleets tyres that don’t just roll but actively help them cut carbon, save energy, and operate more efficiently in a changing world.

A legacy of listening and solving

If there’s one thread running through Michelin’s history, it’s this: innovation built on listening. From the twin drive axle tyre in 1908 to today’s breakthroughs in airless tyres, every step in Michelin’s truck tyre innovation has solved a real problem for transporters.

The MICHELIN Remix® process cut costs. The radial delivered more mileage. The Triomphe Confort made journeys smoother. And now, digital and sustainable solutions are helping fleets prepare for tomorrow.

Plenty of new innovations in tyres have come and gone, but Michelin’s difference is clear: we stay close to the people who actually use our tyres. Drivers, mechanics, fleet managers provide real feedback that drives real progress. In the end, truck tyre innovation isn’t just about tyres. It’s about giving transport companies the confidence to keep on driving!

FAQ:

While not yet mainstream, airless tyres are getting closer to reality. Michelin sees them as a key step toward sustainable mobility, with benefits like puncture-free safety, improved fleet efficiency, and reduced raw material use. Through prototypes and ongoing research, Michelin is showing how airless technology could soon reshape the future of truck tyre innovation.

Michelin’s latest innovations include airless tyre prototypes and research, connected tyres with onboard tyre tread sensors and pressure sensors for smarter fleet management, and tyres made from 45-58% sustainable materials.

Michelin is already reshaping tyres with real innovations ౼ including smart connected tyres with live monitoring for fleets, and designs optimised for EVs and hydrogen vehicles to improve efficiency. The next frontier? 100% sustainable tyres by 2050 ౼ currently at 45-58% renewable materials ౼ using bio-sourced rubber, recycled steel, and plant-based compounds.

gettyimages 930571046

car going fast on a road by night